CHIRON Showcases Next-Generation Machining Solutions at OPEN HOUSE 2025

From May 13 to 15, 2025, the CHIRON Group will open its doors in Tuttlingen, Germany, for OPEN HOUSE 2025. Under the motto “Innovations for future demands – explore our machining world premiere”, the event presents cutting-edge machining solutions and production technologies to a global audience of industry professionals.

Across 1,500 square meters of exhibition space, CHIRON will demonstrate twelve machining centers and turnkey systems in live operation, addressing the needs of various industries. Highlights include a world premiere in micromachining and the high-performance DZ 22 W speed+, a dual-spindle machine built for speed and productivity. The event will also feature 35 partner companies, technical presentations on topics such as friction stir welding and gear manufacturing, and insights into CHIRON’s core expertise areas: Services, Automation, Refurbishment, and Digital Solutions.

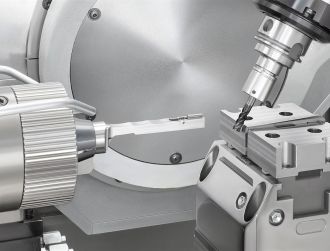

A New Standard in Micromachining

Expanding on proven platforms such as the Micro5 (for workpieces up to 50 mm) and the FZ 08 S five axis (up to 250 mm), CHIRON will introduce a new machining center for components up to 120 mm. This innovation responds to rising demands in medical and precision engineering sectors, with applications including bone plates, knee implants, dental components, and watch casings.

Michael Wurster, Senior Product Manager, explains: “We’re scaling up our successful micromachining concept to enable new application areas. The new machine offers longer travel paths, higher cutting performance, and shorter cycle times—while maintaining maximum precision, dynamic motion control, and resource efficiency.” Full details and the model name will be revealed during the world premiere.

DZ 22 W speed+: Optimized for High-Speed Series Production

Designed for complete machining of large components, the DZ 22 W features a 600 mm spindle distance and is ideally suited for high-volume production. Thanks to optimised kinematics, the new DZ 22 W speed+ variant enhances productivity by up to 10%. Michael Eble, Head of Engineering, highlights key performance data: “We’ve achieved a 20% increase in acceleration and a 40% improvement in jerk control, enabling faster transitions. Combined with a new spindle featuring a 0.5-second ramp-up time and a 2.0-second chip-to-chip cycle, the DZ 22 W speed+ sets a new benchmark in performance for the 22 Series.”

Combined Operations for Maximum Efficiency

The FZ 19 S five axis demonstrates how single-spindle machines can deliver high productivity—even with challenging materials like Inconel and titanium. With 700 mm travel in the Z-axis, the machine is engineered for 5-axis simultaneous machining of both cubic and cylindrical parts.

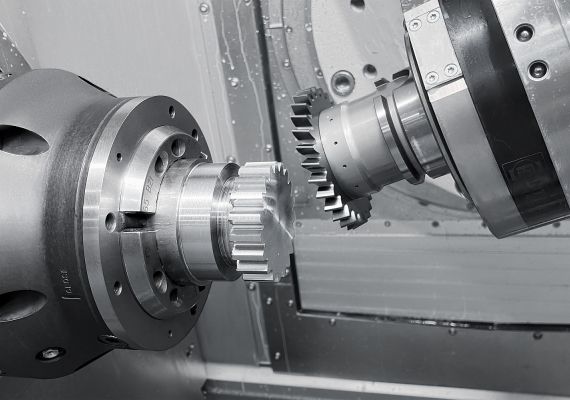

CHIRON also presents the FZ 19 S mill turn and the MT variants of the 715 Series, which integrate milling, turning, and gear cutting in a single setup. This approach improves precision, reduces cycle times, and minimizes logistics and handling—a compelling solution for flexible, high-accuracy production.

In a dedicated showcase, the FZ 16 S five axis will demonstrate the production of structural columns for the Micro5, emphasizing CHIRON’s internal precision standards.

Alternatives to New Investments

For manufacturers not currently prioritizing new machinery investments, CHIRON offers cost-effective alternatives. These include custom refurbishment of existing systems, acquisition of reconditioned machines, and the PerformanceFinance program. This package provides access to next-generation machining technology, IoT-based analytics, and preventive maintenance services—available with flexible 36- or 48-month terms.

A Focus on Technical Dialogue

According to Matthias Rapp, Vice President Global Marketing, OPEN HOUSE 2025 is not only about presenting innovations. “Today’s market conditions demand more flexibility, autonomy, and resilience. Our goal is to engage directly with our visitors, understand their challenges, and identify future-proof solutions that support long-term success in a competitive global landscape.”

-

Gear hobbing, gear skiving (picture), gear broaching, impact gear milling: individually or in combination integrated in the MT machine variants of the 715 Series. -

The Variocell MOVE sets automated workpiece handling on CHIRON machining centers in motion: The compact robot cell can simply be “docked“ where it is needed.