CHIRON showcases latest innovations at EMO 2023

The skill is to pick out the innovations and new developments from the many being presented that can take your manufacturing and production forwards. Whether they focus on productivity, quality or service, the aim is ultimately to implement your own innovations. Under the motto "Innovative Manufacturing", the EMO exhibition will this year quite definitely bring all these together in one place. Anyone using Hanover as an opportunity to discover any kind of innovation for their company will find satisfaction with the CHIRON Group.

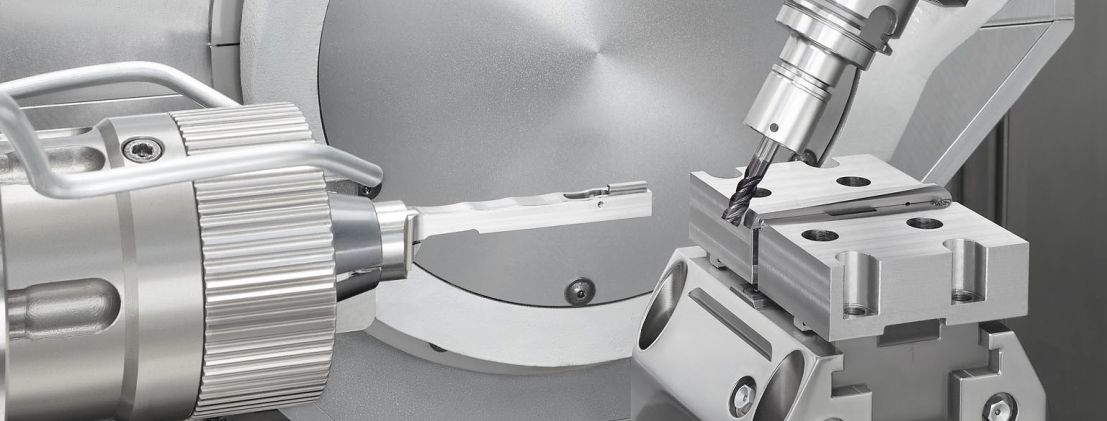

Highlights include the flexible and stable DZ 22 S mill turn for small and medium series. In contrast to a motor housing, the stator housing on a traction motor for electric cars is a classic rotationally symmetric component. The mill-turn solution on one or more DZ 22 S mill-turn machines from the CHIRON Group for machining inner contours and bearing seats simply requires standard tools. Likewise, the clamping concepts for OP10 and OP20 of the mill-turn complete machining solution can be implemented with proven standards. "Manufacturing stator housings using a combination of milling and turning on the DZ 22 S mill-turn is the optimum solution – precise and highly flexible – for small batch sizes through to medium series," Michael Rothenburger, Head of Core Workpieces Automotive, is convinced. "For the motor housing, on the other hand," Rothenburger continues, "the turning process is not as easy to implement – the clamping devices to compensate for the imbalance caused by the protruding flanges for mounting the transmission housing and bearing shield are too complex and too costly. Here we favor machining purely using milling to achieve the required quality. In order to also meet the demand for high productivity, the tools for machining the bearing bore and the bearing seat are developments of the CHIRON Group with its system partners."

15 Series: Premiere of the latest machine generation

More than 4,000 machining centers of the 15 Series have been put into operation since the year 2000 – that's an average of one every other day! A more detailed look at 23 years of key figures for the 15 Series reveals one thing in particular: The machines are amongst the most versatile in the product portfolio of the CHIRON Group in terms of the range of parts and industries. "The machining centers in the 15 Series are popular because of their dynamics and speed, as well as their reliability," says Sales Engineer Markus Schimansky with reference to his customers. The next generation of the 15 Series will celebrate its premiere at EMO in Hanover. It will be controlled with the new Sinumerik One system: Simplified intuitive operation on 22" or 24" touchscreens with Profinet standard. Based on this, the digital systems from the SmartLine portfolio of the CHIRON Group can now be used to their full extent. Schimansky is convinced that the positive effects of smart digitalization will be seen in manufacturing on a highly practical level. For example, with ConditionLine for automatic condition monitoring. Maintenance and repairs can be specifically planned by the system, which in turn increases availability. Another example is the preventive collision protection provided by the ProtectLine digital system, which makes the manufacturing process safer.

The next generation, in addition to the already extensive options provided by the 15 Series, now also includes the own rotary tables of the CHIRON Group. The new RTA220 can now be used for "lightweight" four-axis machining (e.g. of aluminum) in particular. It is wear-free and for 0°/180° positioning, only requires 0.4 s instead of the previous 0.9 s. The basic technical data remains the same – the balance between flexibility and productivity and between performance, dynamics and stability of a machine in the 15 Series has proven itself in day-to-day practice. And ultimately, it is this balance that makes the machining centers in the 15 Series among the most versatile in the product range of the CHIRON Group.

Six-sided complete machining

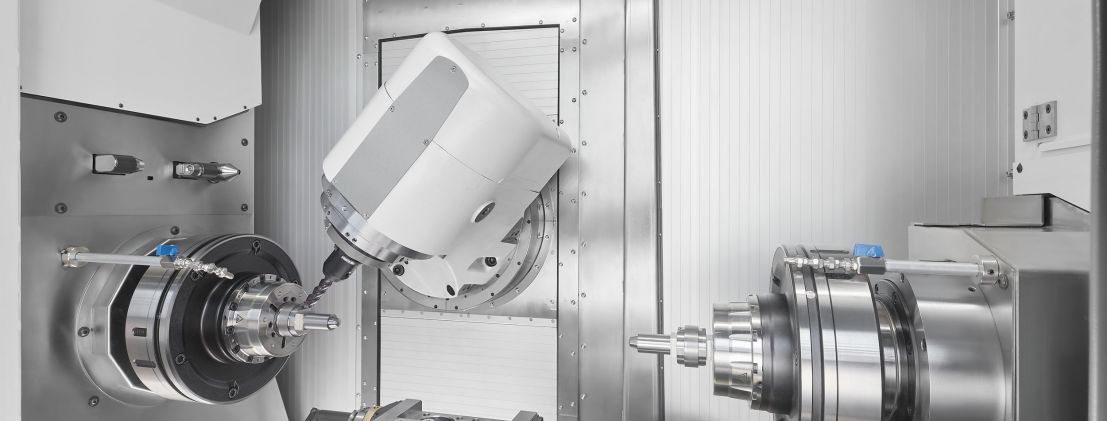

Anyone familiar with the world of six-sided complete machining with milling and turning knows about the benefits when machining highly precise, complex and thus often very expensive workpieces. Even the very first part produced must have the correct dimensions. The MT 715 two+ and the FZ 08 S mill turn precision+ stand up to these demanding requirements at the EMO Hannover 2023. The machining centers demonstrate their performance in action and make it clear why the six-sided complete machining system with integrated automation always means a productivity boost for customers.

Micro5 micro-machining

In a very short amount of time, the smallest and most energy-efficient machine in the product portfolio of the CHIRON Group has become a bestseller. The USPs of the Micro5 are sustainable and ultraprecise. This machining center features an energy requirement of just 0.5 kW/h, a footprint of under 1 m2 and micron-level precision. Together with the automation Feed5, the Micro5 features high autonomy. With a workpiece blank of 50 x 50 x 3 mm(capacity of over 1,200 blanks) and an assumed cycle time of ten minutes, that equates to eight days of automated production. The Micro5 and Feed5 will demonstrate dynamic and productive high-speed milling at EMO and will be a real eye-catcher for everyone working in precision technology.

Versatile automation solutions

Access original spare parts faster and more easily – with myCHIRON, the Service department of the CHIRON Group will present a new customer portal at the EMO, the main focus of which is the new e-shop. In future, customers will be able to access machine-specific parts lists and specifications and order the required spare parts in just a few clicks, 24 hours a day. Full transparency regarding order status, deliveries, and invoices, as well as a direct information flow and faster processes, along with being able to compare the spare parts on offer, are the classic advantages of the new customer portal. Another new feature and the focus of service is the repair and refurbishment of motor spindles.

With PerformanceFinance the CHIRON Group in cooperation with Siemens Finance & Leasing GmbH, offers its first all-inclusive leasing package. The "All-inclusive" includes temporary financing along with data-based condition monitoring and extensive proactive and reactive services, which also aim to provide the promised performance.

Last but not least, a topic that is omnipresent in virtually every company – automating manufacturing processes. The CHIRON Group boasts a wide range of automation options – from robots to integrated solutions, gantry or cell, pallet or conveyor automation.

With regard to "Innovative Manufacturing" – Matthias Rapp, Vice President Global Marketing, is convinced "that the CHIRON Group is ideally positioned and prepared in terms of innovation and that the team will advise and actively support visitors in their search for the best machine, service or complete solution. He also adds that innovation is something that helps customers move their business forwards."