Röhm presents clamping and gripping technology in XXS to XXL sizes

As a clamping and gripping technology specialist, Röhm aims to meet the rising requirements of a wide range of industries. The company continues to strengthen its commitment to the oil and gas, automotive and micro technology sectors. At the current EMO trade fair in Hanover, these were the principal target industries on which the company had set its sights.

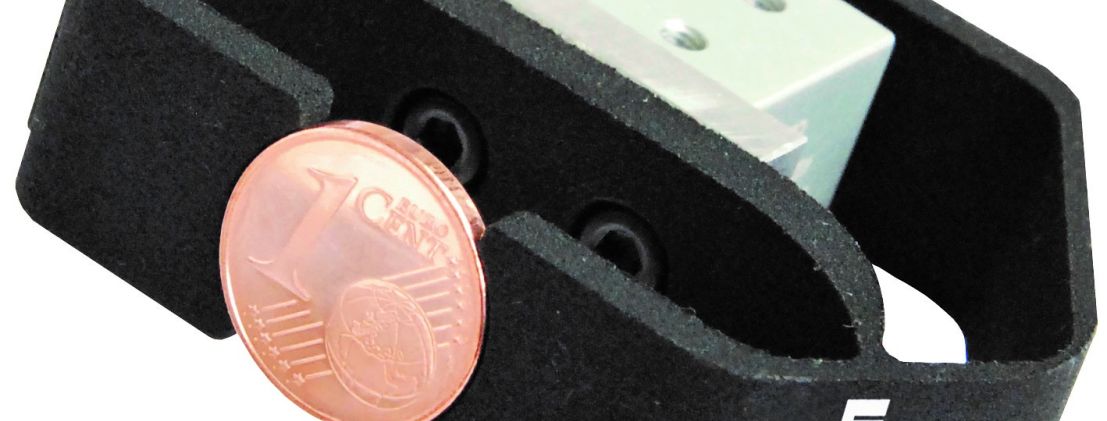

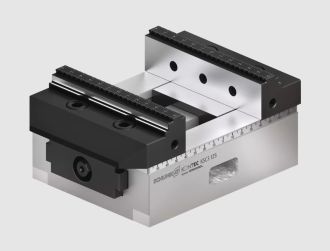

Röhm is proud of its new micro technology product line, which offers clamping and gripping technology for workpieces ranging from the small to the minute. Many highly regarded watchmakers and jewelers create their top-quality products with the help of chucks, vices, gripping technology and other solutions supplied by Röhm. In this branch of industry dedicated to the production of luxury goods, there can be no compromise in matters of quality.

Medical technology sector

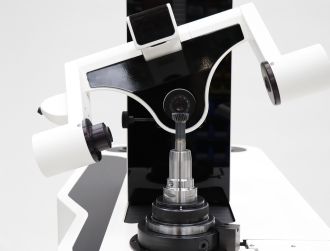

Röhm also focuses on the medical technology sector. Implants for dental technology and for hip and knee joints are made with the help of chucks, centric clamping devices and micro clamping systems from the clamping technology experts. Röhm also makes tool clamping systems for situations where even the HSK 25 is too big. In this way the smallest tools can be clamped securely, either directly without an adapter or with the help of a taper fitting. Dental technology, for example, can involve the processing of implants which are smaller than a matchstick. The different clamping set variants can be combined with a release unit if required.

Oil and gas industry

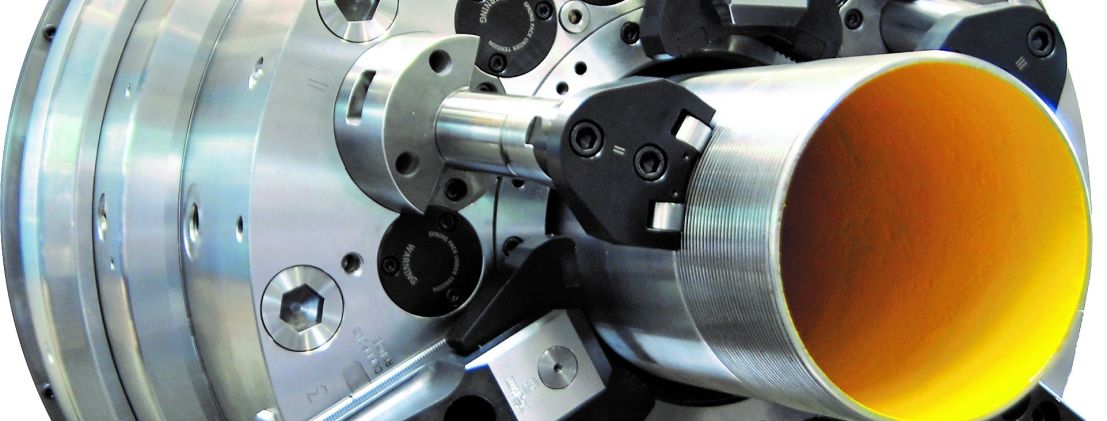

Another sector on which Röhm concentrates is the oil and gas industry. Production of these fossil fuel energy media is presenting the industry with ever more challenging tasks. The increasing difficulty of reaching oil and gas reserves calls for new approaches, as even reserves lying at considerable depth seem capable of yielding profits.

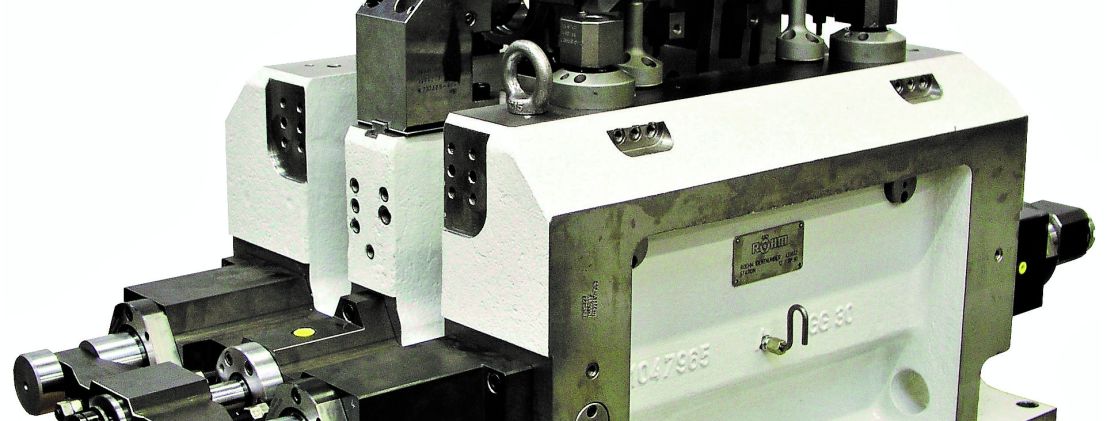

Different versions of the LVE pneumatic front end chuck are thus being used to clamp pipes of large diameter for the production and transport of the raw materials. As an alternative solution, customers can also opt for the HVE hydraulic front end chuck. The new range of indexing chucks is ideally suited for the clamping of sleeves. Sleeves and connecting pieces can be processed from both sides in a single clamping operation. The ring indexing chucks give maximum axial precision while minimising setup times.

Last but not least, clamping equipment for drill heads makes Röhm an all-round supplier, offering what is needed for all processing steps in the oil and gas industry. The special demands in the area of drill head clamping are met with the help of special solutions. So for example the fixed centre drive chuck makes it possible to insert the tapering inner thread of sleeves on both sides simultaneously. Röhm has been successful in developing all-round solutions for all tasks faced in the industry, once again providing a basis for the creation of specially customised clamping solutions.

Automotive manufacturing

Developments in the automotive industry are significantly affected by the demand for speedier processing, more sophisticated technology and higher standards of safety and user-friendliness. In order to meet these requirements, the automotive industry needs a powerful and reliable partner to come up with efficient and economic manufacturing methods.

Röhm has been an important supplier to the automotive industry for decades. Above all, in the field of special solutions, the company has made a name for itself. Automotive manufacturers depend on efficient solutions for all kinds of specific applications. Whether it is a matter of hydraulic or pneumatic clamping equipment for the clamping of engine blocks, cylinder blocks, cylinder crank housings, rear axles, axle pivots, axle housings, rear axle shafts, coupling housings and crankshafts, or clamping systems for rotation-symmetrical components like wheel rims, differential housings, crankshaft bearings, driveshafts, wheel carriers or cogwheels, Röhm is sure to have the appropriate solution.