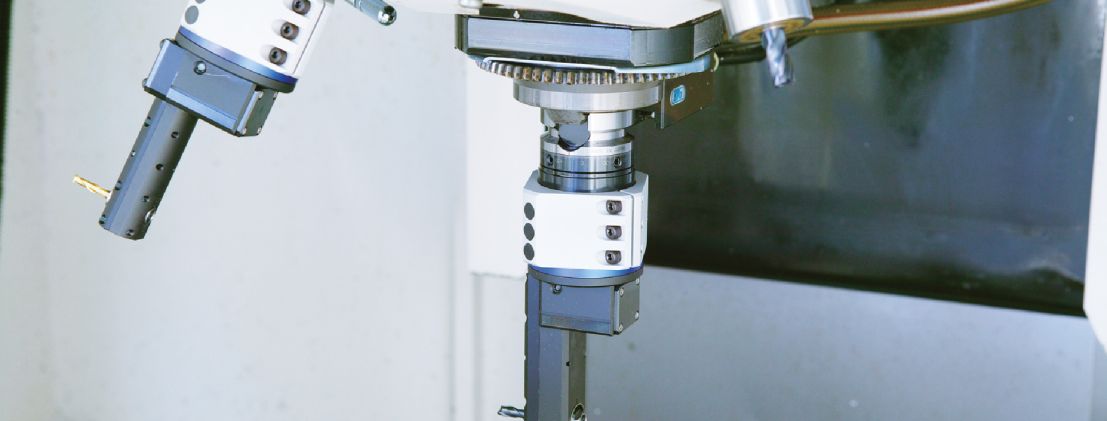

BIG KAISER announces two new lightweight angle heads: a small bore version suitable for tools with diameters between 0.25mm and 6mm, and another optimized for high torque tapping. These new models complement the existing device tailored for general machining applications.

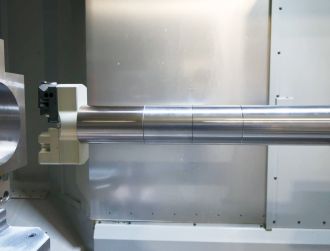

Adding a BIG KAISER angle head allows users to extend their existing machine’s capabilities without the cost of new equipment. These heads facilitate vertical, horizontal, and angular operations without the need to reposition the workpiece, thus increasing accuracy and productivity. This enhancement not only saves machining time but also accelerates production workflows.

Weighing less than 2kg, the new angle heads are part of BIG KAISER’s compact series. Their reduced weight makes them compatible with the automatic tool changers (ATC) of small, dynamic machines, such as those from Fanuc and Brother, thereby making the machines even more versatile. The lighter weight also enables the ATC to operate more swiftly, reducing tool change times and shortening overall cycle times—resulting in markedly enhanced productivity. Designed specifically for the BBT30 machine spindle, the new angle heads include a high-precision BBT 30 interface. The lineup includes three variants tailored for general machining, high torque tapping, and small bore applications.

Giampaolo Roccatello, Chief Sales & Marketing Officer for Europe at BIG KAISER, comments: “These latest models expand our range of angle heads, offering greater choice and flexibility to our customers. For instance, Brother’s CNC machines, which are frequently used in mass-producing small components like valves and mechanical parts, benefit significantly from the reduced weight, resulting in improved productivity, speed, and shorter cycle times.”

The angle heads feature a compact design that minimizes overhang, enhancing both rigidity and strength. An advanced non-contact seal offers superior protection against coolant and particulate contamination compared to traditional sealing methods. Additionally, a unique coolant jacket effectively directs coolant to the cutting edge while cooling the angle head, which helps to reduce noise and vibration.

Crafted from high-quality components including hardened and ground chrome-nickel steel spiral bevel gears, super precision hardened and ground spindles, and high-precision angular contact ball bearings, the lightweight angle heads are available for order now.