Additive manufacturing and finishing with hyperMILL

OPEN MIND Technologies will showcase new CAD/CAM and MES developments at Formnext from November 18 to 21, 2025. At Messe Frankfurt, Hall 12.0, Booth B99, the company will present hyperMILL functions for additive build strategies and the precise finishing of additively manufactured parts, including an integrated module for DED and WAAM and BEST FIT for digital twin-based alignment.

OPEN MIND announces that hyperMILL ADDITIVE Manufacturing extends 5-axis simultaneous machining for Direct Energy Deposition and Wire Arc Additive Manufacturing. Unlike standalone print planners, the 3D printing module is fully integrated into the CAD/CAM suite. The integration is designed to simplify programming on hybrid machines that combine additive and subtractive processes in one setup. The additive toolpaths and process control draw on the company’s established 5 axis and simulation technologies to increase reliability during build and finishing. In parallel, OPEN MIND highlights an approach to postprocessing and rework that uses virtual machine technology to align the CAM environment with the clamped part on the machine tool. The announcement was made in Wessling on September 17, 2025, ahead of Formnext.

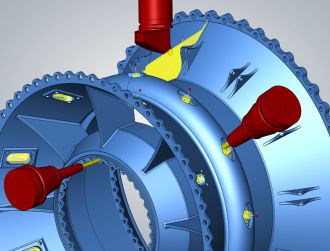

Integrated additive workflow for DED and WAAM

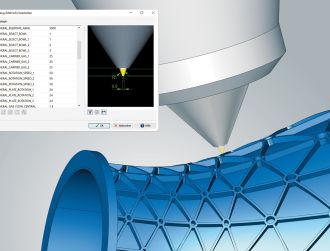

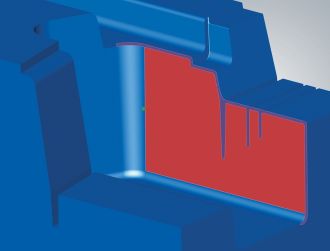

hyperMILL ADDITIVE Manufacturing targets users of DED and WAAM by bringing build strategy definition, collision-checked 5-axis motion and simulation into a single programming environment. The full integration removes data handoffs between separate applications and reduces the risk of mismatches between build and finish stages. The benefit is most evident on hybrid machines where additive deposition and subsequent milling occur consecutively without breaking the setup. Programmers can switch between additive and subtractive operations while maintaining a coherent toolpath model and a consistent digital twin of the machine. The same simulation core that supports the company’s milling strategies is used to validate additive motion, interpass transitions and reachability, to maximize process reliability. For shops qualifying AM parts for serial use, this unified workflow supports predictable deposition on complex geometries and straightforward transition to finishing routines such as adaptive roughing and multi-axis finishing.

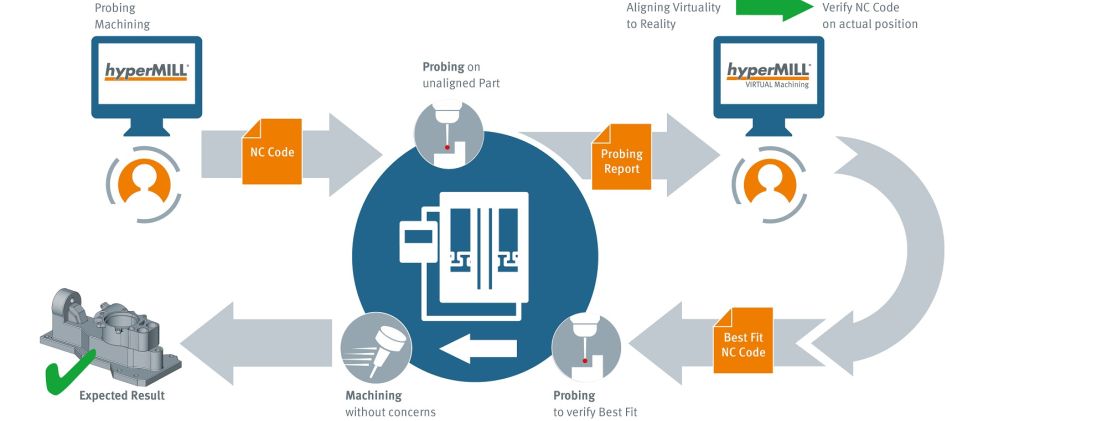

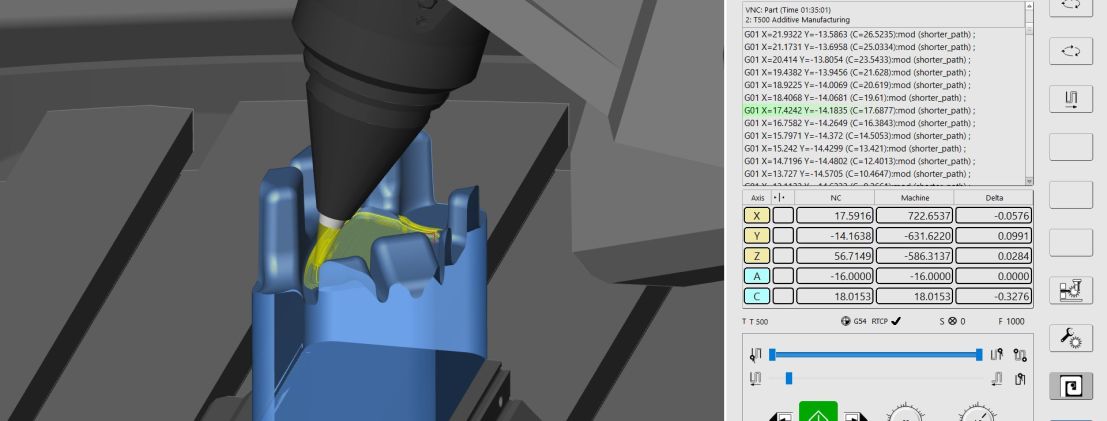

Finishing with the digital twin using BEST FIT

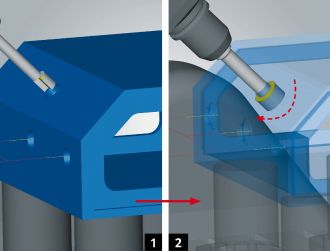

Outside the hybrid case, finishing typically starts from a near-net raw part with small machining allowances that must be aligned and referenced on a milling center. To streamline this step, OPEN MIND introduces BEST FIT within hyperMILL’s virtual machine. The prerequisite is a 5-axis machining center equipped with a digital probe. The misaligned billet is probed directly on the machine, the measurement protocol is transferred back to the CAM system and the NC program is adapted to the actual workpiece position. Instead of manually nudging fixtures and reindicating features, the software reconciles the virtual programming environment with the real clamping situation. This approach reduces manual alignment effort, lowers the chance of positioning errors and accelerates the handoff from additive build to subtractive finishing. For users processing additively manufactured parts with variable stock conditions, BEST FIT provides a consistent method to bring the digital twin and the physical setup into agreement, supporting efficient, precise and reliable rework.

OPEN MIND will present these capabilities at Formnext 2025, Hall 12.0, Booth B99 in Frankfurt, with a focus on integrated additive strategies and digital twin-driven finishing that support dependable shop floor execution.