Index presents more than just turning at AMB

At the 20th iteration of AMB, the industry forum for metalworking experts being held this year from September 13 to 17, Index will be showcasing its extensive product range. At its heart are the new Index G220 and Traub TNX220 turn-mill centers, plus the equally new iXcenter robot cell in size L. Also on show: the Index ABC and C200 automatic production lathes, the Traub TNL12 sliding headstock lathe, and the Index MS24-6 multi-spindle machine. The machines will be flanked by info and advice counters for the digital Index iXworld and sector-specific applications.

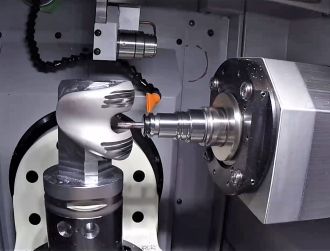

The turning specialists from Esslingen are meeting the trend for demanding complete machining with the new generation of the “small” Index G220 turn-mill center and the Traub TNX220 turn-mill center, the latter celebrating its premiere at the show and of identical design apart from the control and drive technology. Both machines feature a spindle clearance of 76 mm, a chuck diameter of 200 mm, and a turning length of 900 mm. The innovation they embody sets standards in terms of productivity and flexibility. A mineral cast bed and generously dimensioned linear guides ensure ideal stability and damping properties, as well as excellent dynamic values. Particular hallmarks include the motorized milling spindle with the hydrodynamically mounted Y/B axis and also the two tool turrets located at the bottom. Together, these features enable flexible and highly productive complete machining.

Complementing the two turn-mill centers, Index also presents the new size L iXcenter, extending the automation cell series to all sizes between S and XL. Similar to the XL version, the iXcenter L consists of a robot cell placed in front of the machine, to which various modules can be docked from two sides – these include pallet/rack modules, measuring/testing stations, equipment for deburring, cleaning or laser marking, and much more. This enables complete automation of the process chain from machining to packaging.

Index ABC automatic lathe now with Y-axis

A further highlight at the Index booth is the new version of the successful Index ABC CNC automatic lathe, which is characterized, above all, by major improvements in the upper turret. These include an electronic Indexing axis, Y functionality, height adjustment, and the ability to fit double tool holders. But despite all these innovations, INDEX has retained the valued features of the previous, successful model: The machine design, the working area, and the footprint are all still exactly the same. As before, the INDEX ABC is controlled by a Siemens S840D sl or a Fanuc 31i-B, the latter of which will be on show at AMB.

The successful Index C-series automatic production lathes open up a wealth of possibilities for the rapid production of complex turned bar stock parts. At the INDEX booth, this will be demonstrated by a C200 with Fanuc control. An Index C100 with Siemens S840D sl will be on show at the “Special show for young people” in the atrium near the east entrance. There, the “Young Mechanical Engineers’ Foundation,” in cooperation with industry partners, will be inspiring young people to explore metalworking careers. And the Index C100 is nothing if not inspiring. Watching simultaneous machining with three turrets on the main and counter spindles is like a masterclass in high-tech.

Improved sliding headstock automatic lathe

Back to the Index booth, and the impressive Traub TNL12 sliding headstock automatic lathe. Like its larger cousins, it can now be easily converted to a fixed headstock and also offers the ideal prerequisites for a significant increase in productivity when it comes to small high-precision turned parts. Compared to its predecessor, the new version on show at AMB has a more compact design with further improved kinematics.

The Index MS24-6 CNC multi-spindle automatic lathe enables highly economical turning operations. It is more compact than its predecessor, the MS22-6, but still allows for a slightly larger bar diameter of 24 mm. In view of decreasing batch sizes, the optimized setup concept is extremely important. This is helped by the Index quick clamping system with integrated W-serration on the cross slide.

Complementing the greater bar diameter of the MS24-6 is the new Index MBL24-6 bar loading magazine, which offers all the usual MBL benefits regarding smooth bar movement and vibration reduction during machining. It is available as a bundle loader and a bar loader in sizes of 3300 mm and 4300 mm.

New mobile iX4.0 app

Index is a pioneer in the digital environment, not just in machine technology. For many years now, the cloud-based Index iXworld platform has been developing at a rapid pace. Its central element, the Index iX4.0 IoT platform, offers numerous iX4.0 apps that provide application and efficiency-focused digital support for the entire process chain.

Brand new is the iX4.0 iXmobile app for iPhone and Android, which iXworld users can install via the Google Play Store or the Apple App Store. You can then easily add your machines and view the current production status at any time. You receive notifications when production stops or problems are imminent. This enables them to quickly detect and prevent costly downtimes, especially in low-manned or unattended operations.

The iXshop procurement portal makes it easy to purchase tool holders, accessories, clamping devices, spare parts, and much more. The iXservices service portal can be used for machine management—including fault, repair, maintenance, and care management. The Index specialists will be available to answer questions here, especially on the topics of refit and virtual machine.

Last but not least, Index will present its partner company One Click Metal at AMB, a provider of additive manufacturing solutions in which the Esslingen-based company has been a majority shareholder since March 2021. With a workforce of about 20 employees, One Click Metal develops comprehensive solutions in the field of metal 3D printing for small and medium-sized components.