The world of metalworking is undergoing significant changes. Industries such as automotive, medical technology, and mechanical engineering are presenting new challenges that many manufacturers need to address. At AMB 2024, INDEX will showcase the latest turn-mill centers, multi-spindle machines, production lathes and automation solutions to meet these evolving demands.

At AMB (Hall 4, 4C30), two new models will demonstrate how INDEX has further adapted its offerings to meet customer needs: On the INDEX G200.3, the previously rigid upper turret now features a pivoting Y/B axis, ideal for angled drilling and milling operations. Another new highlight: the INDEX G320 compact. Equipped with a 102 mm main spindle, this turn-mill center has the footprint of a G220.3 but is nearly as powerful as the regular G320 – and saves a great deal of space, resources, and costs. Both machines will be showcased in their long versions with 1,200 mm turning lengths for the first time at the show.

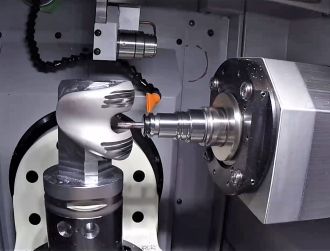

Another INDEX turn-mill center will also be featured at AMB: an INDEX G220, which can be seen at the Paul Horn booth (Hall 1, 1I10). The two companies are linked by a technology partnership aimed at improving processes for high-speed whirling, hobbing, bevel gear cutting, groove turning, and polygon turning.

Multi-spindle automatic lathes

The INDEX multi-spindle automatic lathes are always an impressive appearance. While their importance in the automotive industry has somewhat declined, they are increasingly gaining ground in other markets. At AMB 2024, the Esslingen-based lathe manufacturer will unveil its newly developed INDEX MS24-8 to a wide audience for the first time. This multi-spindle machine offers a 24 mm bar clearance and features eight main spindles, up to two hydraulically locked and extremely fast swiveling synchronous spindles, and up to 16 tool carriers, showcasing unparalleled versatility. Whether it’s complex parts or different processes like polygon turning and thread cutting – anything is possible. The INDEX MS24-8 will demonstrate this live on a technology component, proving its suitability for industries such as medical technology, jewelry and watchmaking, mobile hydraulics, sanitary fittings, and contract manufacturing with a broad production spectrum.

Automatic lathes

Ideal for compact production spaces is the TRAUB TNL32 compact Swiss/fixed headstock automatic lathe, which combines the small footprint of the TRAUB TNL20 with a bar clearance of 32 mm. The TRAUB TNL12 has also been equipped with new features, allowing it to be easily converted from a Swiss to a fixed headstock lathe, just like its larger siblings.

Highly productive bar stock machining is a hallmark of the INDEX C200 and INDEX ABC automatic lathes, available with both Siemens and Fanuc controls. At AMB, the C200 will be showcased in the Fanuc variant, while an ABC with Siemens 840D sl control will also be on display. The C200 comes from the INDEX Refit program, where it was completely overhauled mechanically and electrically by reprocessing specialists after over ten years in production. The highlight of this service was the control upgrade from a Siemens 840D PowerLine to SolutionLine, making the machine even more powerful than in its original delivery condition.

Additionally, INDEX will present an INDEX C100 production lathe for the SONDERSCHAU JUGEND fair organized by the Youth Foundation of Mechanical Engineering. At booth 010, Entrance East, this machine will be used to manufacture rims for a Formula 1 model car.

Partners

There will be several partners on the INDEX booth. The Japanese machine tool manufacturer Makino with whom INDEX has a global sales cooperation, will present the a40 SE horizontal 5-axis machining center. The machine will be automated by the INDEX iXcenter L robot cell.

Also present will be INDEX’s partner company One Click Metal, which offers additive manufacturing solutions. Their team of around 20 employees develops comprehensive 3D metal printing solutions for small to medium-sized components.

Last but not least, INDEX digital specialists will explain the practical benefits of the digital INDEX iXworld. They will present numerous iX4.0 apps, demonstrating how the iX4.0 IoT platform ensures transparency and productivity throughout the entire machining process chain. Also, they will show how efficiently the iXshop can be used for the procurement of spare parts and other tools, as well as the advantages of iXservices in after-sales service.