Makino N2-5XA 5-axis machining center for the first time at AMB

From 13 to 17 September 2022 Makino is presenting the N2-5XA 5-axis horizontal machining center for the first time at the AMB in Stuttgart. The N2-5XA is specifically designed for high productivity in near-net-shape components, making it ideal for medical part machining of orthopedic implant parts and high-volume die cast component production

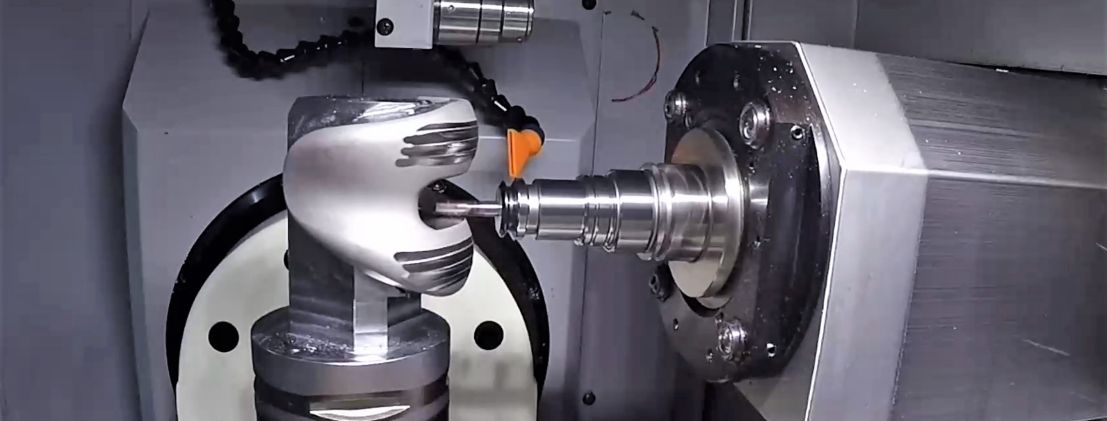

This 5-axis horizontal machining center is designed to change the paradigm of implant manufacturing. With its design, it is possible to manufacture implants while avoiding water cooling due to the unique chip-free design of the machining chamber. With the Professional 6 NC-control and direct-drive rotary axis, it is also possible to manufacture the smoothest of components.

High stability and rigidity

Making small parts does not mean you need to compromise. Makino understands that small parts are big business, even if a full day of production only yields a shoe box full of parts. Small part manufacturers face many challenges, from small part material issues with titanium, cobalt, chrome or stainless, to the model options to choose from when thinking about a new machine purchase. Commonly available machinery can make you feel like you have to make a decision between going with the larger machine that consumes too much floor space or settling on a small machine that lacks rigidity. These challenges are common in all sectors whether, medical, dental, electronics or aerospace, and can lead to compromise. Compromises like these hit your bottom line with reduced productivity and profitability. The N2-5XA has been developed to incorporate stability, rigidity and productivity into a compact machine design. It's twin direct-drive rotary axes are housed in a rigid trunnion casting, providing ideal access to the workpiece and opportunities to improve quality and throughput by consolidating operations.

The N2-5XA features a 20,000 rpm HSK-40A spindle that accelerates to maximum RPM in just 0.8 seconds. This spindle works in concert with the standard AI Contour Control and 1.4G Z-axis acceleration to quickly and accurately produce the complex geometries common in medical implant components. Consuming a minimum floor space, the N2-5XA is a high-productivity ‘right-size’ solution for small part manufacturing challenges. The machine is suitable for a maximum workpiece size of 300 mm x 270 mm and a maximum payload of 150 kg.