Hurco Focuses on Accessible Automation

From September 10 to 14, 2024, Hurco will present automation solutions at the AMB in Stuttgart, aimed at making machining more efficient and precise. In light of the skilled labor shortage and increasing competitive pressures, Hurco emphasizes automating small and medium-sized production runs. A key highlight at Hurco's booth will be the VM 10UiPlus equipped with ProFeeder automation.

The ProFeeder Tray enhances productivity for the VM 10UiPlus. Featuring a universal parts tray, this system facilitates quick batch changes for a variety of components. The cobot is designed specifically for small to medium-sized series. The UR10e robotic arm handles machine loading, and the ease with which the ProFeeder Tray can be transferred to other Hurco machines ensures system flexibility. The Automation Job Manager, fully integrated into the MAX5 control, eliminates the need for additional programming.

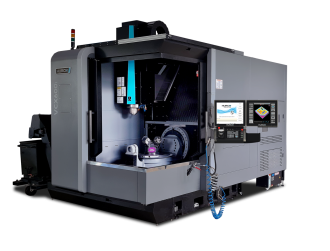

Compact Five-Axis Machine

At AMB, the ProFeeder Tray will be demonstrated in conjunction with Hurco's VM 10UiPlus. This compact five-axis machine is tailored for the precise manufacturing of small workpieces, thanks in part to its robust construction, linear guides on the X, Y, and Z axes, wide swivel ranges in the A and C axes, and extensive control and software features. The machine’s 11 kW spindle with an SK40 holder and a maximum speed of 12,000 rpm ensures high productivity. Furthermore, it is equipped with the WinMax MAX 5 control featuring conversational programming. Visitors will have the opportunity to experience this technology firsthand at the booth. Information about Takumi brand machines, part of the Hurco Group, will also be available.