Cellro presents high-mix-low-volume production at AMB

The latest robotic cells presented by Cellro at the AMB in Messe Stuttgart clearly demonstrate the manufacturer's vision. Namely, Cellro wants to enable machining companies to respond quickly and flexibly to customer requests. The automation of high-mix-low-volume production has always been a spearhead for this. At the AMB, the manufacturer will be demonstrating a new functionality that will help make this possible.

At the AMB, Cellro is putting the spotlight on the new intelligent function 'Job verification'. With this functionality, the controller automatically checks whether machines, materials and all other supplies are available for the tasks to be performed. This allows the operator to avoid interruptions in automated production. This contributes to achieving the maximum number of spindle hours. Moreover, with Job verification, the manufacturer manages to make unmanned production more predictable. In this way, the threshold for machining companies to start with unmanned production is lowered even further.

Easy automation

In addition to Job verification, Cellro is also presenting various accessible robotic cells during the AMB, including the Xcelerate X20 and X35. Xcelerate has been on the market for some time and is designed to load one to two machines with workpieces simultaneously. From lathes to milling machines and from grinding machines to measuring machines. Xcelerate is available in several models. For example, the X20 presented by Cellro is suitable for product handling of workpieces up to 35 kg. The X35, on the other hand, provides more flexibility in the choice of fixturing. This system in fact combines pallet and product handling.

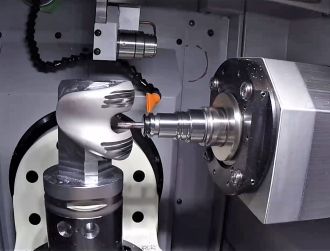

Six-sided machining

The Xcelerate X20 will be on display at AMB with an R-C2 unit and a product takeover station. This universal solution is designed to process products on six sides in an automated manner. The compact system won the TechniShow Innovation Award in 2020 and is suitable for machining small series or single pieces - sequentially or interchangeably. Machinists can use this cell 24 hours a day to machine milled parts up to 250 mm x 150 mm x 150 mm and up to 15 kg on six sides.