How reliably is 5G technology driving industrial automation?

The new 5G wireless standard promises to drive digitization by means of real-time communication. However, how reliable and stable is the technology in use cases involving the automation of industrial production? Professor Dr. Hans Schotten, head of the "5G Kaiserslautern" research project and the Chair of Radio Communication and Navigation at RPTU Kaiserslautern-Landau, is conducting research on this. At the Hannover Messe, he and his team will provide insights into two projects at the "5G Kaiserslautern" booth (Hall 14, Booth H06/02) from May 17 to April 21.

Increasing shortages of skilled workers and the desire to save costs in the long term are the key drivers accelerating digitization and automation in industrial production. In order to be able to implement flexible solutions, wireless communication in real-time is key, as promised by the 5G mobile communications standard. The technology enables large volumes of data and safety-relevant information to flow back and forth quickly and process steps to run at the required pace.

Professor Schotten's team at RPTU is investigating whether 5G-based solutions can deliver on this promise for relevant application scenarios. At the Hannover Messe, the researchers will focus on the following project:

Transport by robot

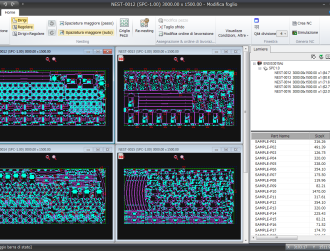

The team is testing intralogistics robots for the transport of goods on a site, for example factory premises or a university campus. For this purpose, the researchers have two types of vehicles (up to 75 kg payload and up to 10 kg payload) in use at the RPTU. The delivery orders can be created automatically or triggered by pressing a button in a control station. Once the order has been initiated, the robot drives (semi-)autonomously to the transfer point, picks up the delivery and brings it to the destination. The entire fleet of vehicles can be tracked on a monitor wall in the control center. In addition to the camera images, all the sensor data, information on driving time, the current location and the package contents can be viewed there. This only works with the high data rates of 5G technology, because each individual robot requires a high upload bandwidth. It reports any problems or unknown situations to the control center, from where an operator takes over control via the 5G network – as fully autonomous driving under demanding real-world conditions is not possible yet.

In the next step, or as soon as upcoming releases further increase the performance of the 5G mobile networks, more and more computing resources are to be outsourced from the robot to an edge cloud in order to reduce the complexity of the vehicles, their weight and energy consumption. Ultimately, this could make (semi-)autonomous transport vehicles more interesting for industrial customers, as this also reduces the purchase price and enables longer operating times.