AMADA's approach to smart manufacturing is complete & flexible

EuroBLECH 2016's theme, “the new generation of sheet metal working”, highlights how the metalworking industry has to adapt its production processes to the market trends. Lot sizes decrease steadily, the demand for assembly work increases, and extreme flexibility and speed is requested in the processing of materials and thicknesses that are always changing. All this must be done at the most competitive price possible along with maximum quality and profitability. With 70 years of experience, Amada will showcase this October a complete & flexible approach to smart manufacturing, in order to make new opportunities out of these challenges.

VPSS 3i complete suite

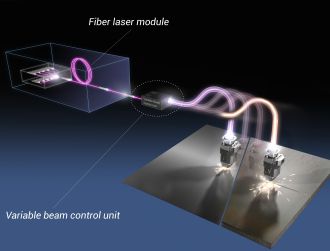

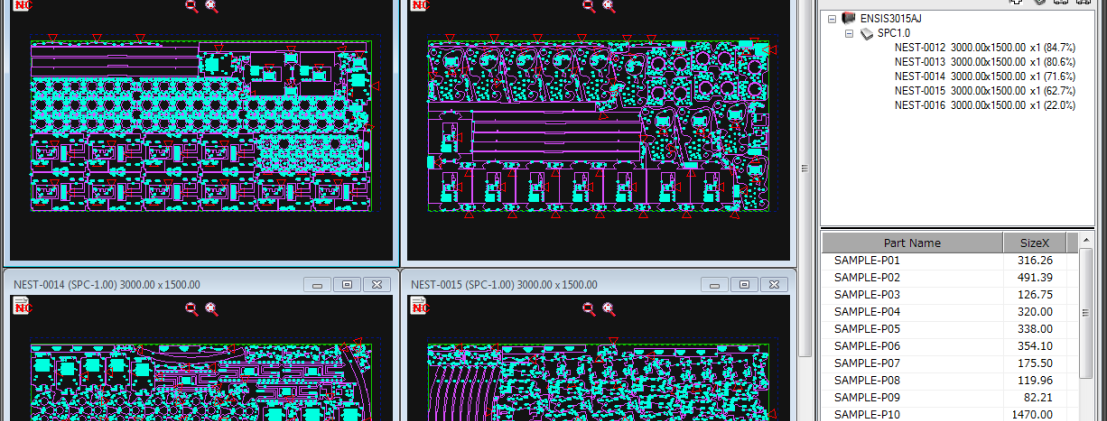

Listening to its customers’ voices as well as the market needs, Amada developed the VPSS 3i Software Suite. Based on reverse engineering and virtual prototyping concepts, the VPSS 3i suite allows unified programming of all Amada technologies (blank, bend and weld). It efficiently simulates and verifies each production step to prevent any possible error, to ensure the best production results.

Created to answer the customers’ needs and for their success, Amada's VPSS 3i suite aims to become the backbone of their factories and the reliable support to their production. The VPSS 3i suite and all associated software are part of Amada’s wider approach to Smart Manufacturing: V-factory.

V-factory

Amada’s V-factory project embraces the whole production cycle in order for the customer to manage and optimize their entire factory. By introducing a high degree of intelligence, through smart scheduling, for example, Amada’s virtual factory significantly reduces costs and waste of time and resources.

Amada's digital software solutions ensure the best performance from every Amada machine, and the Navi EU module also allows the integration of other manufacturers machines just as efficiently.

Amada’s visionary digital approach is etched in the principles of Industry 4.0, providing a basic tool for companies who want to easily adapt to current and future market demands. Amada aims to remain a reference point as a provider of complete manufacturing solutions to its current and future clients.

Amada’s V-factory was conceived as a set of complementary technological building blocks, covering three levels: smart shop floor control, advanced processing technologies and optimized workflow services. This concept thus aims to let metalworking manufacturers integrate their factories at their own speed, with each building block still offering distinctive, cutting-edge results.

Amada’s V-factory and 3i solutions, standing for interactivity, integration and intelligence, prove that once again, Amada is staying abreast of industry trends. This tailored approach to smart manufacturing aims to fit sheet metal manufacturers’ needs, for their success and the success of their own customers.