DMG MORI CELOS X Paves the way into the Future of Manufacturing

At this year's Open House in Pfronten, DMG MORI presented the CELOS X. Around ten years after introducing the world's first app-based machine control system DMG MORI is revolutionizing manufacturing technology once again. The CELOS X ecosystem offers unique consistency across all DMG MORI control variants for a manufacturing company’s Digital Transformation (DX).

With CELOS X, DMG MORI is pursuing a holistic, customer-centered approach to innovation. As a result, the CELOS X ecosystem comprises a constantly growing assortment of digital products and applications as well as data-based services. CELOS X offers unprecedented consistency across all DMG MORI control variants. CELOS X consists of the two components CELOS Xperience and CELOS Xchange. CELOS Xperience provides as a direct level of user interaction with applications and software systems. The cloud-based CELOS Xchange platform offers a centralized and secure data space for the end-to-end integration of the shop floor. The interaction between the functions and capabilities of CELOS X offers a unique user experience and seamless digital interoperability. CELOS X impresses with its wide range of functions, performance and consistency. To be more specific, the content of CELOS X is available to almost the same extent on all control versions offered.

CELOS Xchange: The central data platform

CELOS Xchange acts as the multifunctional control center of the CELOS X ecosystem and, in particular, orchestrates the entire application and data management at the CELOS Xperience level. “As a cloud-based data hub, CELOS Xchange also enables the bidirectional integration of the manufacturing workshop into the company's IT and, in the future, the open and secure exchange of data with partners along supply chains and within global value creation networks,” explains Dr. Tommy Kuhn, Managing Director of DMG MORI Digital GmbH. In combination with DMG MORI's standardized machine connectivity, CELOS Xchange impresses with its high scalability and interoperability with third-party machines and partner applications. Security and data sovereignty are the top priorities. The customer can determine at any time, which data is synchronized with CELOS Xchange. In addition, the foundation for access to current new and further developments is built here.

Efficient access to manufacturing information: CELOS Xchange offers a central data platform for the collection, aggregation, and utilization of manufacturing data. Companies can store and manage their data in one place, which improves efficiency and access to relevant information.

Communication across system borders: CELOS Xchange achieves the possibility of bidirectional integration of the manufacturing workshop into the company's IT. As a result, companies can seamlessly connect their manufacturing processes with other systems and software solutions, such as ERP or CAD/CAM, and ensure smooth communication and data transfers.

Horizontal integration: CELOS Xchange opens the prospect of open and secure data exchange with partners along the supply chain and within global value creation networks. Companies can share data securely through the corresponding data hub and optimize their cooperation with external partners.

From data to added value: CELOS Xchange lays the foundation for the analysis and evaluation of manufacturing data. Based on the gained knowledge companies can monitor the performance of machines and their manufacturing processes transparently, identify imminent bottlenecks and initiate measures for continuous improvement.

CELOS Xperience: Digital toolbox

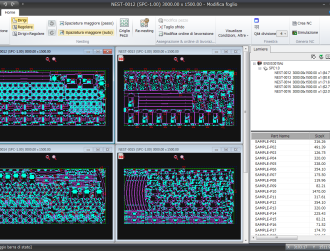

CELOS Xperience is the digital toolbox for all applications and software systems within the CELOS X ecosystem offering more than 30 apps and continuous workflows. The available solutions demonstrate the holistic added customer value of CELOS X. All applications and workflows aim to simplify machine operation and increase spindle hours, while at the same time optimizing energy efficiency.

Intuitive user interface: CELOS Xperience offers a user-friendly and intuitive user interface, where users can access all relevant information and applications quickly and without any CNC specific knowledge. The seamless integration of apps and technology cycles into CELOS X on the control improves the efficiency and user experience and simplifies the operation of machine tools.

Comprehensive functionalities: CELOS Xperience achieves a wide range of functionalities, which go beyond the control of machine tools. The functionalities span from improving processes during preparation and maintenance to monitoring, and thanks to the no-code platform TULIP even applications provided by the customer can be integrated.

Machining Transformation with CELOS X

With the launch of the CELOS X ecosystem, DMG MORI's Machining Transformation (MX) also gains further strength and momentum. As an integrative link from the NC control system to the CELOS Xchange data hub and with open interoperability from the shop floor to higher-level system environments, CELOS X is the basis for Digital Transformation (DX). In addition, the functionality and performance of CELOS X also contribute to the three other MX pillars of Process Integration, Automation and Green Transformation (GX). Taken together, CELOS X provides Machining Transformation (MX) with comprehensive benefits that have a positive impact on productivity, quality, costs, working conditions and flexibility and promote the environmental sustainability of manufacturing. CELOS X thus becomes a crucial tool for DMG MORI's customers to remain competitive in a highly competitive and rapidly evolving market environment.