AMADA launches eco-friendly ACIES-AJ punching & fibre laser cutting combination machine

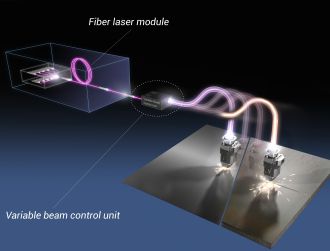

As an addition to the ACIES combination series (originally with a CO2 laser source), the ACIES-AJ, with a servo-electric drive and fiber laser technology, is characterized by cut quality, speed and energy efficiency. This machine is equipped with several functions to realize long-term, continuous operation.

This new machine, available with 2 kW or 4 kW fiber laser power, benefits from lower running costs while maintaining high-speed efficient processing of thin and reflective materials. High productivity and energy savings are therefore guaranteed. A fully covered brush bed prevents scratches and allows high-quality processing.

To protect effectively from the laser light, the laser is enclosed in a full table cabin with a second X origin position. Tools set up errors are drastically reduced thanks to the ID Tool system which also promotes the optimum tool maintenance process. Automation of part picking and sorting reduces production time and increases efficiency and the automatic nozzle changer enhances continuous operation.

Key characteristics of exhibited machine

|

Punching force |

300 kN |

|

Punching drive |

Twin servo-electric |

|

Laser power |

4 kW |

|

Working range |

3000 mm x 1500 mm |

|

Turret |

32st-4AI |

|

Tool storage |

300 tools |

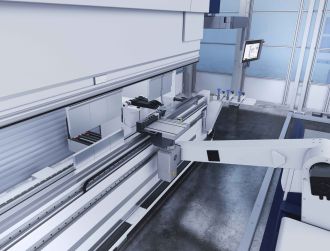

Key characteristics of exhibited automation machine

|

Material size |

Min. 900 mm x 900 mm Max. 3000 mm x 1500 mm |

|

Thickness |

0.5 t – 6.0 t |

|

Stacking weight |

3000 kg/pallet |

|

Shelf height |

10 shelves |