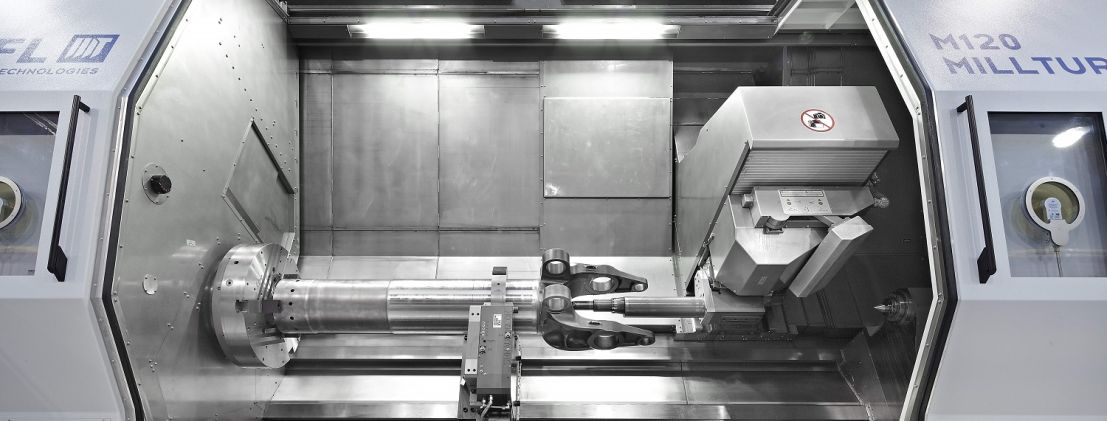

WFL presents the newest machine models at the Technology Meeting

From March 16th – 19th WFL Millturn Technologies presents not only the newest machine models, but also innovations in the areas of software and especially technology, at the Technology Meeting in Linz, Austria. Professional visitors will have the chance to collect first-hand information from the machining experts of WFL and from a variety of leading providers of tools, clamping devices, measuring devices and CAD-CAM systems.

At the recently expanded headquarter in Linz, WFL Millturn Technologies exhibits daily from 09:00 am to 05:00 pm the entire spectrum of machinery, ranging from the M35 MILLTURN to the M150 Millturn. With this high-tech-product portfolio, complex workpieces in nearly all sizes can be manufactured efficiently, with low costs and completely. Multitasking machining from A-Z in the production area, in-process technologies and innovative scientific talks in the field of manufacturing can be experienced.

Integrate new technologies practice-oriented

This innovation forum of machining will present a broad range of technologies: ID-machining, gear cutting, additive manufacturing by means of a high-performance laser, laser-hardening, and surface treatment by machine hammer peening are part of the highlights

Deep-hole drilling and complex ID-machining are among the top core competences of WFL. Another field of expertise is the different gear cutting techniques. The M40 MILLTURN showed five different gear cutting techniques, enabling the customer to use the MILLTURNs more efficiently. Requirements, which years ago sounded like pure fantasy, are nowadays standard repertoire of complete machining. With complex applications, WFL especially emphasizes on user-optimized and economical solutions.

Additive Manufacturing

Additive manufacturing methods with a high-performance laser were presented on the M80 Millturn. With this procedure a broad spectrum of materials can be utilized. The repair of the wearing area and the composition of protection layers is made possible. Also laser-hardening and laser-welding open new manufacturing methods for the customers.

Machine hammer peening, a WFL patented solution for complete machining centers, was presented on the M35 Millturn. This technology is applied at critical areas of workpieces and the rework of surfaces. Thereby, the surface quality and hardness is improved and inherent compressive stress is realized. Likewise, for narrow tolerances and high surface requirements, grinding was presented on the M65 Millturn. This process allows the compliance of the narrowest tolerances whereat WFL developed unique machining cycles for this procedure.

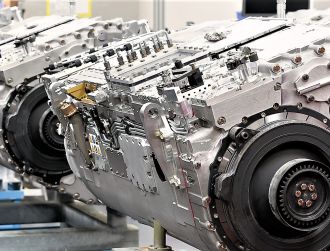

High-End Millturn

Another emphasis of WFL for a long time already is titanium machining, a material that needs a special processing and well-grounded know-how. Titanium machining was exhibited at the M120 MILLTURN and professional visitors could visualize the progress achieved. During the Technology Meeting an aerospace workpiece was manufactured and the more efficient and easier processing of the material demonstrated. Through tool supervision and tool laser measuring paired with the usage of a special coolant, higher safety during the machining process is ensured.

The M50 MILLTURN presented the enhanced screw machining with a special programming tool. Thus, WFL also stays active in the plastics industry. The newly developed, innovative light concept, “Ergonomic Light Concept”, was also shown on the M50 Millturn. The enhanced concept with LED-lamps allows a perfect illumination of the workpiece, the tool and the working area.

Ready for Industry 4.0

Another highlight of the Technology Meeting were the topics of Programming, Simulation, Production & Service. Not only the MILLTURNs are developed continuously, but also the software to facilitate the operation. With the possibilities of software solutions by WFL regarding the provision of operating, tool and process data for superior software systems the company shows the readiness for Industry 4.0. WFL follows the trend in the production technology and enables easier coordination of the internal procedures of the customer.

New Paths

After finalizing the extensive enlargement, WFL appears in a completely new look. A state-of-the-art customer centre is available to receive and host visitors. A competence center, consisting of a measurement laboratory and an investment in the greatest possible Zeiss measuring machine model, has been established in order to bring measurement to the next level. Rapid spare part availability is significantly improved thanks to the extension and modernization of the spare parts depot. The overall office space has been enlarged as well in order to fulfill the needs in accordance with the rising market success.

Besides all the innovations presented, WFL doesn’t forget heavy machining and the efficient use of all turning-, boring- and milling operations. New technologies and innovations in the field of complete machining presented at the Technology Meeting of WFL gave a promising outlook into the future. In addition, visitors had the possibility to experience leading expertise in complete machining live.