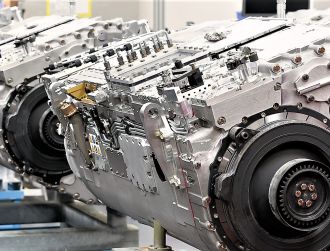

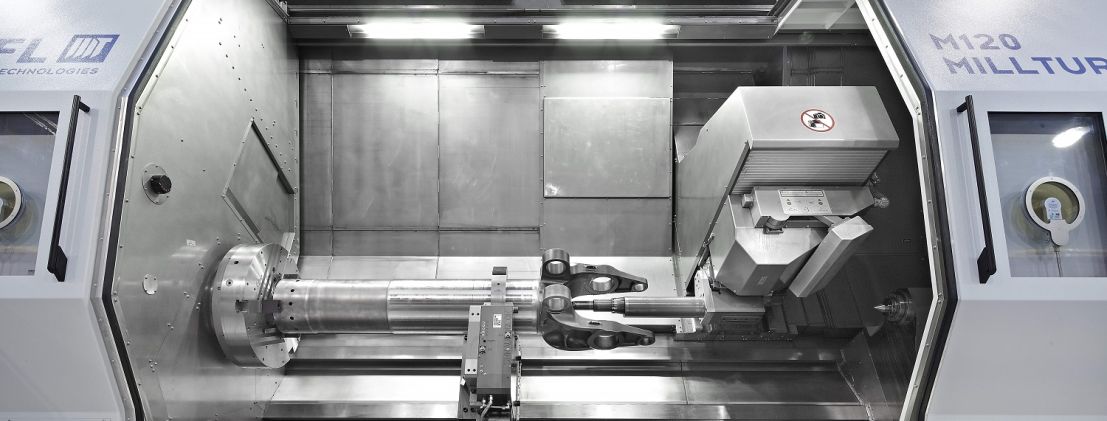

Machining titanium aircraft landing gears with Millturn technology

Heavy-duty cutting places particular requirements on the machine and working processes. If this involves a material such as titanium, which is particularly hard to cut, specific know-how is necessary to deal with these requirements. The aviation industry represents an important market segment for WFL. This industrial sector increasingly requires ever more materials that are deemed to be difficult to machine. Titanium machining in particular is a field in which WFL shines with its wealth of expertise.

Titanium has always placed particular demands on tools and machines during the cutting process. In recent years titanium 3.7165 has become prevalent among lightweight materials as a material with outstanding properties, especially in the aviation and space industries and also in the medical sector. It is one of the most frequently used titanium alloys, containing 6% aluminium and 4% vanadium. This alloy, normally referred to as Ti6Al4V, exhibits a very good combination of strength, corrosion resistance and capacity to withstand stresses. Although this material does have good empirical values and cutting data, processing it still remains one of the supreme disciplines in machining.

The titan of all metals

New titanium alloys are constantly being developed for special applications and these are often on the basis of specific customer requirements. A number of WFL customers require Titanium 5553 (Ti5Al5V5Mo3Cr) for the production of landing gear in the aviation industry. This material stands out due to improved properties with regard to strength and toughness. It is also less sensitive to structural changes during heating. This material is indeed one of the real Titans in the field of machining and takes its name from Greek mythology. Ti5553 is at present one of the hardest materials on the market to machine. A cutting speed of 45 m/min should not be exceeded when it is being processed as shear stresses of up to 2,780 N/mm² can develop at cutting speeds as low as 60 m/min.

Challenges in titanium machining

Problems like point heat due to poor heat conduction and associated chemical changes in the material (embrittlement at higher temperatures) and the formation of built-up edges occur to a greater extent with this material than with other titanium alloys. Therefore it is vital that cutting speed, feed rate and penetration depth are matched to one another accurately when working with Ti 5553. The use of suitable cooling lubricants is just as important as the correct cooling strategy. A quick and continuous removal of swarf must be guaranteed; the heat dissipation occurs to a much greater extent via the tool. Removal of the forging skin, referred to as "elephant skin" by experts, is an additional challenge with this material. The upstream forging process and the resultant thermal and metallurgical influences give this skin a very high level of surface hardness.

The low modulus of elasticity means that titanium tends to evade the pressure of the tool and to fuse with the cutting edge. The machining should, therefore, occur at a low cutting speed but with a relatively high and even feed rate. Vibration-free, clamped, sharp tools must be ensured in any case. High-speed steels with a high cobalt content, carbide or Stellite are used as cutting materials.

Experience is the decisive factor

All this shows that titanium calls for a lot of experience in the selection and use of the tools as well as the machining strategies. It is essential that the ability to cater for critical aspects of machining during manufacture is demonstrated as early as the design phase. For example, it is necessary to consider the fact that different material thicknesses in the blank workpiece require modified machining strategies. Heat-affected zones must also be taken into consideration together with the cutting forces which occur.

Materials that are hard to cut like titanium have influenced the development of the WFL machines. WFL provides individual solutions for exactly these demanding applications. These also cover aspects such as cooling and production strategy as well as the actual machine. "In order to be able to offer WFL customers reliable solutions, WFL has developed components which make it possible for us to match the design of the machine precisely to the relevant application case." – Reinhard Koll, Head of Application Engineering WFL.