Bredel brings flexibility to automated turning-milling processes

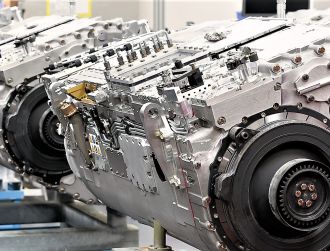

Bredel in Delden, manufacturer of industrial hose pumps, has invested in a M65-G MILLTURN turning-milling centre from WFL. In order to make the best use of the productivity and capabilities of the turning-milling centre, the WFL machine tool is equipped with a large tool magazine, an automation solution from Promot and a jaw quick-change system from Schunk specially developed for this project. With the complete installation, Bredel can produce various parts for hose pumps unmanned and achieve short throughput times.

Bredel is part of the Watson-Marlow Fluid Technology Group and the global market leader in the field of hose pumps. The pumps make their way to clients in a wide variety of industries, from mining through to the medical and food industry. To maintain its competitive edge, Bredel is always looking for ways to improve productivity and optimise processes. The new automated WFL M65-G MILLTURN is a great example of the continuous investment strategy at Bredel. The new turning-milling centre will eventually replace an older machining centre from WFL. At the moment, all programs and components are gradually being optimised and transferred to the new M65-G.

Combining machining processes

Bredel has not only replaced the old CNC machining centre from WFL due to its age and capabilities, but also because they wish to use the new machine for production for 120 hours per week, with staff required for just one day shift. In order to achieve this, Bredel has opted for an automated production process. Bertus Groteboer, Senior Manufacturing Engineer at Bredel explains: “The decision to opt for a new turning-milling centre was already on the cards. At the end of the 90s, we had already decided that we were only going to invest in machines that can perform both turning and milling operations. Although these types of machine are much more expensive, the ROI is significantly better. This is because machining processes can be combined, which means that two separate machines are no longer necessary. Bredel can therefore fully machine pump parts with both turning and milling operations in one clamping.”

Producing pump parts as a set

The new WFL M65‑G has a nominal centre distance of 2,000 mm. Both spindles have an output of 56 kW. The two spindles and milling spindle allows for complete machining of workpieces. “In this project we actually focused on unmanned production. The production cell takes the material out of the storage and after machining, places the finished workpiece back in the storage without any human intervention. Here, it is important that various workpieces can be produced interchangeably. In this way, we can produce the different parts of a pump as a set, with the advantage that we can sell and paint faster. To make this possible, the machining centre must have several important elements that not only allow for an unmanned production process, but also a high degree of flexibility.”

Optimisation in the small details

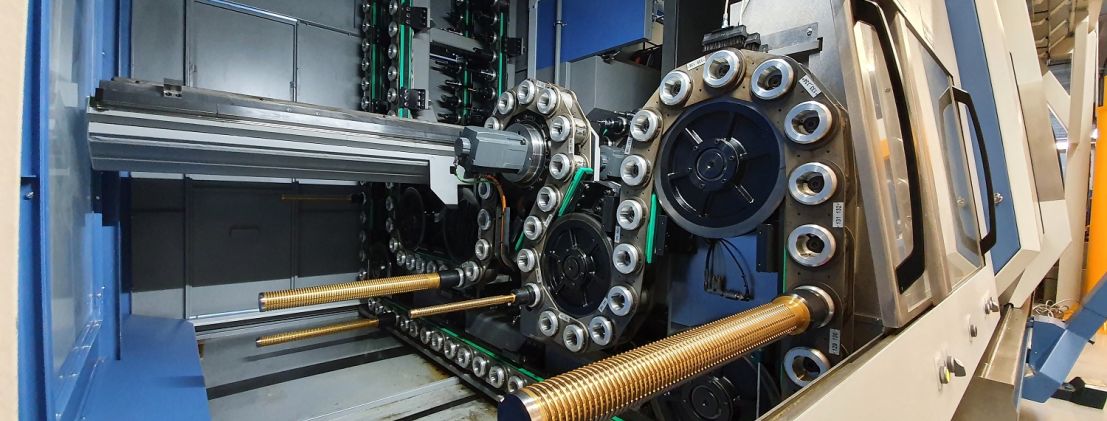

In order to machine a wide variety of parts automatically, Bredel has equipped the turning-milling centre from WFL with a large chain magazine. The magazine has room for a total of 200 tools, while taking up relatively little space, just a few square metres. The magazine’s special feature is that it can accommodate tools with a length of up to 900 mm. This was a particular requirement of Bredel to be able to store long broaching tools. “For this project, we took a critical look at the cutting tools. A working process can always be improved and the tools play a crucial role. Take, for example, combined tools to reduce tool change times or special tools that can perform a process much faster. All these little things help to reduce throughput time and lower the cost of the workpiece. This is the only way businesses in the Netherlands can continue to compete with the rest of the world,” believes Groteboer. In order to machine gearings and grooves, Bredel has developed a special broaching tool in consultation with WFL. Usually, the tool needs a feed force of 100 kN, which was not achievable even with the WFL machine. The adapted version has a feed force of just 30 kN. Whereas previously the shaping of gear teeth in a part took half an hour, the process takes just 1.5 minutes using the adapted broaching tool.

Throughput time more than halved

Thanks to the new automated turning-milling centre that can machine small batches flexibly, Bredel has reduced the throughput time for a set of pump parts from three days to just one day. What’s more, the manufacturer can respond much more quickly to urgent orders. “We have optimized the design of many workpieces in order to make the best possible use of the machine’s capacity. Parts for milling-turning operations have therefore become more complex. For this reason, we have created a digital twin of the machine together with Siemens and WFL for simulation in the Siemens NX CAD/CAM software. In addition, we have integrated some cycles from WFL such as measurement cycles, process control and engraving into Siemens NX. This means that we can program complex parts offline quickly and reliably.” Bredel is aiming ultimately to achieve 5,500 spindle hours per year with the new M65-G Millturn.