WFL masters deep hole drilling with Millturn machining centers

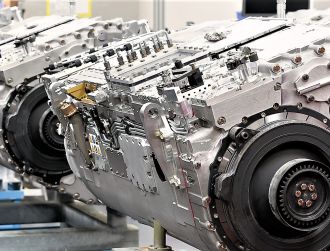

Deep hole drilling counts among the special disciplines within the field of machining, particularly as these kinds of machining steps usually require special equipment in terms of both tools and machines. As a machine manufacturer, WFL equips the machine in such a way that it has a number of decisive advantages over a classic deep-hole drilling machine.

Almost all industries that utilise complete machining have workpieces that require deep-hole drilling. Ultimately, it is the tasks performed in the respective industry that give rise to differences in the process. In the aerospace industry, it is necessary to machine materials such as titanium, Inconel and other heat[1]resistant alloys. Deep hole drilling is challenging with these materials because the tools are subject to heavy wear and controlled chip breakage requires special measures. As a machine manufacturer, WFL requires comprehensive expertise when it comes to using the right tools and selecting the optimum cooling lubricant.

Deep holes in the plastics industry must exhibit extremely high cylindrical dimensional accuracy. Some of these workpieces are subsequently honed to ensure the required quality can be achieved. When performing deep hole drilling in the crankshaft industry, on the other hand, accessibility is vitally important because the oil holes are manufactured in a wide variety of angular positions. The decisive factor here is a flexible machine concept, which facilitates reaching a wide range of angles without setup work for drilling the corresponding holes. Perfect accessibility is possible here thanks to the swivelling B-axis of the Millturn machines.

Stable tool clamping

WFL develops special tool accommodations - partly to ensure stable tool clamping, but above all to deliver the correct coolant pressure and volume directly to the cutting edge of the tool. In a fully automatic sequence, it is also possible to change very long deep-hole drilling tools. With WFL, an automatic tool change can be performed by means of a pick-up magazine and a prismatic tool changer.

A precise pilot hole forms the basis for good results in deep hole drilling, whereby WFL creates a pilot hole directly in the workpiece to guide the long, unstable drill. These pilot holes are produced with an oversize of < 20µm to a depth of 1.5x the hole diameter. The utmost precision is guaranteed, thanks to workpiece measurement and WFL measuring cycles. When producing centric holes, the workpiece and tool can be rotated in opposite directions to further improve the quality of hole centre deviation.

Coolant pressure versus coolant volume

Millturn machines offer different options when it comes to the coolant supply. For small hole diameters, for example, the cooling lubricant is fed directly through the milling spindle at a coolant pressure of up to 200 bar, while the coolant volume is conversely decisive for larger hole diameters. It is fed automatically to the tool accommodation via a bypass line. The enclosed working area of the WFL machines is essential with such high coolant pressures and volumes.

Automatic workpiece measurement and adaptive control

Due to the long tool exposure, deep drilled holes are subject to hole centre deviation that increases with the hole depth. These machining errors cannot be fully eliminated, even when machining on Millturn machines. A particularly interesting machining method is therefore employed here.

Hole centre deviations are measured by intelligent in-process measuring following the completion of deep hole drilling. This is performed either with an extended measuring probe or by means of ultrasonic wall thickness measurement. This involves measuring the thickness of the wall at various circumferential positions and calculating the middle of the centre hole. New clamping points are then produced on the workpiece concentrically to the defective deep drilled hole by means of turn-milling. This allows the completion of all subsequent machining processes with very close form and position tolerance to the deep drilled hole.

The specially developed process monitoring system WFL iControl is used to detect tool breakages or tool wear at an early stage. Such monitoring systems are important in internal machining because the operator has no view of the machining point. The system therefore prevents tool breakages - which endanger the tool and the workpiece - or keeps their effects on the workpiece and the machine to a minimum.

The advantages at a glance:

- Complete machining in one machine

- Fully automatic process due to automatic tool change

- Optimum production method for the respective machining situation

- Integrated, automatic measurement

- Finish machining by means of rolling or honing on the same machine on which drilling was performed

- The cooling lubricant, which is essential for deep hole drilling, can be fed right up to the cutting edge of the tool. This results in a lengthy tool life and reliable discharge of the chips from the hole during the process.

- Very high feed forces of up to 50kN in the Z-axis ensure drilling of large hole diameters.