TRUMPF presents robust fiber lasers for highly productive industrial use

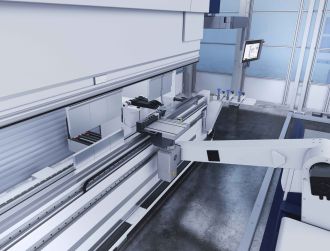

TRUMPF has introduced a new generation of fiber lasers designed for high-precision welding across multiple industrial applications. These lasers, showcased at LASER – World of Photonics in Munich, promise increased productivity and improved component quality in sectors such as electric mobility and precision manufacturing.

The new TruFiber series is positioned as a core component of TRUMPF’s integrated laser systems. According to product manager Tom Rentschler, the lasers are optimized for use with programmable optics and sensor technology, offering manufacturers a way to boost output without compromising accuracy. This capability is particularly relevant for demanding applications like battery welding in electric vehicles, where precision and reliability are critical.

High beam quality across a wide power range

The TruFiber lasers are available in power classes ranging from 500 watts up to 50 kilowatts, covering a wide spectrum of use cases in industrial production. These lasers can be seamlessly combined with TRUMPF's broader ecosystem of laser technology, including beam guidance systems, fixed and scanner-based optics, and real-time status monitoring tools.

A key feature is dynamic power control, which enables consistent, repeatable welds, especially when working with materials like copper. This control mechanism enhances process stability and weld quality even under variable conditions. TRUMPF's full-system integration—spanning lasers, controls, optics, sensors, and cooling—ensures a tightly coordinated production environment. As Rentschler notes, this integration, along with the fiber laser's robustness and high beam quality, makes it an ideal choice for industrial users prioritizing precision and efficiency.

Simplified service and user-friendly operation

In addition to technical performance, TRUMPF has emphasized ease of maintenance and operation. The TruFiber lasers are equipped with integrated sensors that support remote monitoring of key functions. This capability helps reduce downtime by identifying potential process issues early. Should on-site service be required, the laser's modular architecture allows for rapid replacement of components, minimizing disruption and cost.

Another notable enhancement is the redesigned user interface, which mimics the intuitive operation of smartphones. The simplified control system programming and touchscreen-style navigation reduce the learning curve and allow operators to adapt more quickly. Rentschler highlights this usability as a distinguishing feature in the laser processing market, underscoring the company's focus on making advanced technology more accessible on the shop floor.