New TRUMPF gripper boosts productivity for automated bending processes

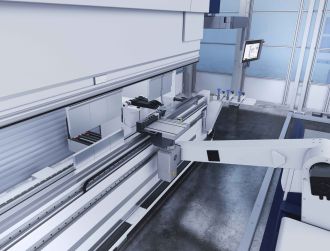

TRUMPF introduced a new and versatile multigripper that delivers greater productivity for automated bending processes. The innovative vacuum gripper is fitted to the TRUMPF BendMaster robotic arm. Up to 12 grippers can be positioned in this way. Using these grippers, the BendMaster is able to remove a workpiece from the stack, move it reliably and efficiently within the bending cell and then place it on the stack for finished parts.

The new multigripper can be set up much more quickly than conventional vacuum grippers. Whereas a conventional gripper has to be modified for each new workpiece, all necessary adjustments for the new multigripper can be made at the system level. This reduces the time needed to set up the bending cell. “Two challenges facing sheet-metal processors are small-batch production runs and a shortage of skilled labor,” explains Bernhard Fischereder, director of product management and international sales for bending at TRUMPF.

“The TRUMPF multigripper makes it economic to use automated bending processes even for smaller batch sizes. Any company – even those already well advanced in the area of automation – can increase their efficiency with the multigripper.” The gripper is available in two variants: small (S) for the transport of workpieces up to four kilograms in weight, and medium (M) for workpieces up to 35 kilograms. Using these two variants, companies will be able to cover a wide range of parts.

Suitable for small batches

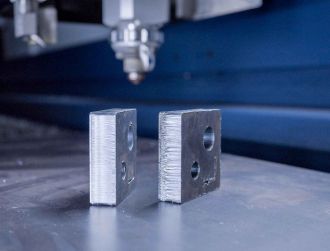

As a rule, the automated production of small batches in the sheet-metal industry is regarded as uneconomical. This is because the gripper has to be modified for each new workpiece, a process that requires a number of manual steps. For example, operatives have to cut metal sections to size, attach brackets and suction cups, bolt all the components together and then connect them with hoses at the appropriate points. This often requires several hours in the workshop. Moreover, there is a shortage of skilled labor at the present time, and operatives proficient in such activities are not always available. The new multigripper from TRUMPF can be adjusted to handle a new workpiece in a matter of minutes. With the M-variant, each of the eight suckers can be adjusted and replaced by means of a hex key. Minimal expertise is required to perform this operation. As a result, it is much quicker and easier to set up the gripper for a new workpiece. Moreover, with the M-variant, each of the suckers can be individually activated. This is useful when handling workpieces with complex geometries.

Faster handling of workpieces

In addition, the new multigripper offers highly efficient and versatile handling of workpieces within the bending cell. The S-variant, for example, features a swivel joint that rotates through 180 degrees. This means that the multigripper can turn over workpieces without having to put them down – something which conventional gripper systems are unable to do. This reduces cycle times. The multigripper is ideal for companies that have a TRUMPF bending cell and are looking to boost their productivity. In particular, job shops will profit from this solution, since they have to undertake frequent gripper modifications in order to bend new workpieces.