Trumpf TruLaser Weld 1000 makes easy entry into automated laser welding possible

Many sheet-metal fabricators still rely on manual welding, which is both costly and time-consuming. The alternative is automated laser welding, but today’s systems tend to be large, expensive and complex to operate. Companies need low-cost solutions to get a foothold in this business – but these are few and far between. The TruLaser Weld 1000 from Trumpf fills a gap in the welding market. It enables smaller companies to enjoy the benefits of automated laser welding, so they can boost the productivity of their production processes and gain a real competitive edge. The new system is particularly suitable for job shops that weld products such as electrical cabinets, sheet-metal boxes and covers.

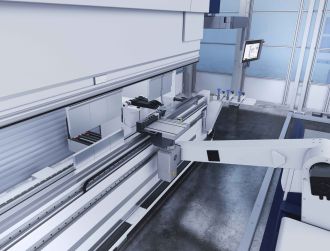

The TruLaser Weld 1000 makes programming quick and easy. Unlike most commercial systems, it does not require employees to spend several days attending training courses. Instead, all the necessary information can be obtained through e-learning. The system incorporates a robot whose operation is based on the concept of a collaborative robot, or cobot. However, its six-axis articulated arm enables it to move much faster and more precisely than a standard cobot, resulting in higher-quality weld seams and less non-productive time. The operator manually guides the robot over the seams on the part that needs to be welded, pressing a button to mark the relevant waypoints. The software then creates the welding program. “Depending on the part, this style of programming – where you simply guide the robot along the seam – takes a matter of minutes. So it’s also a good choice for small-batch production,” says Geiger. With its compact format and dimensions of 5,200 x 2,200 x 2,800 millimeters, the system will fit most manufacturing facilities and can typically be installed and commissioned within a single day.

Double the work area at the touch of a button

Efficiency is a key selling point of the TruLaser Weld 1000. One example is the way in which the Trumpf developers have divided the work area into two sections with a partition. While the robot is welding a part on one side of this partition, the operator can load and unload the machine on the other. Once the welding process is finished, the robot automatically switches to the other side along a linear axis and starts work on the next part. This saves time and boosts productivity. If the operator wishes to weld larger parts, the partition can be automatically raised to provide a work area that is double the size. To maximize safety, the Trumpf developers have installed a wall behind the robot to ensure that no laser light can escape during welding. This keeps employees safe when they are working right next to the robot.

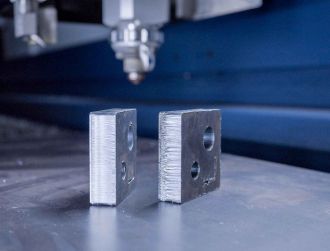

High-quality welding of thin sheets

Trumpf has opted for a three-kilowatt solid-state laser as a beam source. This high-power laser energy rapidly penetrates the sheet when and where it is needed, making it easier to weld thinner sheets of up to four millimeters without distortion. In most cases, no post-processing is required, so companies can save time and cut costs. The Trumpf laser system is also a great choice for processing thicker sheets.