The TruLaser Cell 3000 is a versatile multi-axis machine that offers cost-efficient laser processing of 2D or 3D components, producing high quality results on small or medium sized components. In addition to the Additive Manufacturing Systems Trumph offers costumers, this machine can be featured with the laser metal deposition (LMD) technology package.

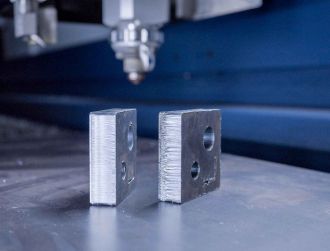

The LMD additive manufacturing process is used for cladding or to add volume and structures to existing parts. It uses a laser beam to generate a melt pool on the surface of the component (substrate) before a stream of metal powder is blown into that melt pool and fused to the substrate. Fabricators can apply highly precise layers, both in overlap and size, using this technology.

Versatile in production quantity and materials

This technology is suitable for one-off prototypes to high-volume production. With solid-state laser options providing up to eight kilowatts of laser power, the machine can process many materials including nonferrous metals. Processing metals is simple since the focal position is adjusted to the thickness of the sheet metal by the operating software. It is also possible to expand the diameter of the focus. This enables fabricators to cut materials of different thicknesses or to switch between welding and cutting applications without changing the focusing optics.

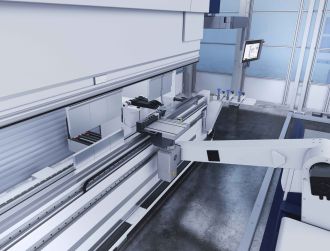

Modular design and minimum floor space

The Trumpf TruLaser Cell 3000 requires only a minimum floor space since the electrical control, cooling units and laser optics are all integrated into the machine. Its modular design allows the laser machine to adapt to different requirements in the production environment.