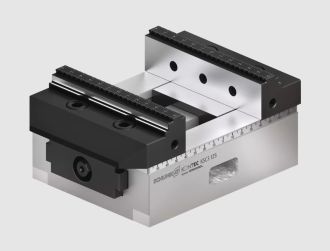

SCHUNK VERO-S NSR3 Expands Pneumatic Coupling Range for Robot Pallet Handling

SCHUNK has further expanded its range of pneumatic couplings for pallet handling with robots. The new powerful VERO-S NSR3 138 robot coupling ensures process-reliable handling of heavy pallet weights. For the first time, the individual clamping statuses can be reliably detected and transmitted to the machine control system via the IO-Link interface.

The maintenance-free robot couplings of the VERO-S NSR series have been setting benchmarks for high-efficiency, robot-assisted pallet changes on machine tools for many years now. Now SCHUNK, the automation technology, toolholding, and workholding expert, is making the handling of heavy pallets safer and further expanding its portfolio for high-end pallet loading.

With the new VERO-S NSR3 138 robot module, SCHUNK is now launching an extremely dimensionally stable module with high pull-down forces, which can absorb higher moments (My = 1,500 Nm and Mz = 1,600 Nm) than its slim, interfering-contour-optimized counterpart VERO-S NSR 160. The blow-off function integrated as standard ensures optimum cleaning of all reference surfaces and thus a process-reliable sequence. The module clamps thanks to spring force via a form-fit, self-retained locking so that the full pull-down force is maintained even in the event of a pressure drop.

Process-reliable clamping

Transparency in the clamping procedure is provided by the optionally combinable AFS3-R IOL 138 monitoring unit, which allows the "module opened", "module closed", "module closed with clamping pin" and "pallet presence" statuses of the robot module to be recorded and transferred to the machine control via the standardized IO-Link interface for the first time. This is a fieldbus-independent point-to-point connection that enables events as well as process and service data to be exchanged between machine control and clamping device and can be integrated into almost any fieldbus system.

High process reliability

The module is hermetically sealed and all functional parts are made of hardened, stainless steel, ensuring a long, maintenance-free service life. Locking is done in a form-fit and self-retaining manner. For unlocking a pneumatic system pressure of 5 bar is sufficient. The use of non-oiled air is also possible. The repeat accuracy amounts to 0.02 mm