MR Components, a medium-sized company from Grigno, Italy, has significantly increased its production capacity and simultaneously improved quality by introducing intelligent automation with EMAG machines. The company, which specializes in the production of parts for differential and planetary gears, now produces around 80,000 components per month, with some of the machines running unmanned in the evenings.

Alessandro Reguzzo, the founder and Managing Director of MR Components, started in 1995 with just one CNC lathe in a garage. Since the business grew quickly, Reguzzo invested in additional machines and moved to a larger production hall. In 2006, the company built its first production hall with 2,500 m². In January 2024, the company finally moved into its new, modern 6,000 m² headquarters. Reguzzo sees the key to success in the consistent automation of production. "The use of automated machines was the key to speeding up production," says Reguzzo. "The machines run unmanned, allowing us to produce in the evening hours without having to introduce a night shift." MR Components relies on EMAG machines that are equipped with integrated measuring probes. "This allows us to check all components 100%," explains Reguzzo. "The stable design and high quality of the machine components are essential in batch production in order to stand out from the competition."

Flexible manufacturing systems

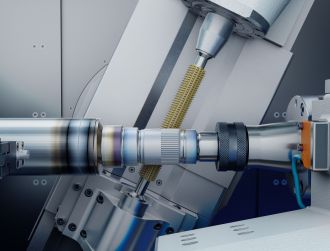

The company uses various manufacturing systems from EMAG to meet the different production requirements of its customers. "In one of our production lines, we work with VL 7 machines, where the operator manually places the workpieces on the automation belt," explains Reguzzo. "In other production lines, we work with VL 4 machines that are equipped with TrackMotion automation. Here, the automation is very fast and we have greater autonomy, so we can also run the machines in unmanned mode." There are also other manufacturing systems, VL 4 and VL 6, which are automated with robots. The decision was made to use a system with robots here, as many components have to undergo other operations in addition to turning, such as marking, which can be carried out very easily and flexibly with the robot.

-

MR Components' modern and highly automated machinery. The company continuously invests in the latest technologies in order to offer customers the best possible quality. -

A robot at work on a production system from MR Components. Automation allows additional operations, such as marking, to be carried out flexibly and easily.

"Free" production hours in the evening

Unmanned production in the evening hours allows MR Components to significantly increase its production time. "We call this time 'free' hours, as it allows us to produce without additional personnel costs," explains Reguzzo. "This is a great advantage, as it is difficult to find staff for the night shift these days."

MR Components has planned further investments for the future. "We are planning to use two VL 8 machines in combination with robots to machine components with a diameter of up to 450 mm," says Reguzzo. "We also want to further develop our gear cutting and assembly technologies to be able to offer our customers even more comprehensive solutions."