Mazak Unveils New CNC and CAD/CAM Software for Tube Cutting at Tube 2024

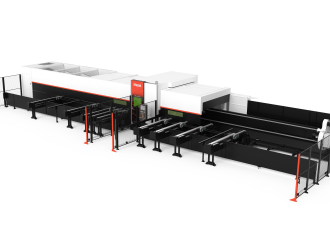

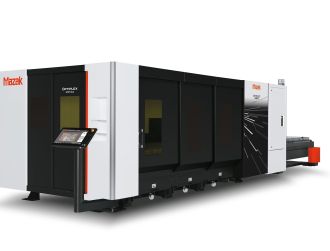

Yamazaki Mazak is bringing the FT-150 FIBER laser tube processing machine designed for high-speed cutting of small to medium-diameter tubes, to Tube 2024. The machine will be controlled by a new tube-cutting CNC that is being exhibited for the first time in Europe.

The FT-150 FIBER can cut round, square and rectangular pipe with diameters up to 152.4 mm – dimensions that are typically used in the construction, furniture and architectural industries, as well as for vehicle body frames. For the first time in Europe, the machine will be controlled by SmoothTUBE CNC. It features a new Graphical User Interface that makes the utilisation of the control simple and intuitive and also a new Human Machine Interface that has several benefits for the operator, including easy production scheduling and programming. With the dual monitor, it is also possible to run multiple applications simultaneously, such as production status and cutting conditions. The large 21.5-inch screen on both monitors enables checking of the machine status with the touch of a finger.

FT-150 FIBER

The FT-150 FIBER can cut a wide variety of materials, such as mild steel, stainless steel, copper, brass and aluminium, and can perform multiple processes including cutting, tapping and thermal drilling. The machine maximises productivity by reducing the requirement for secondary processes such as punch press, deburring and hole tapping.

Key features are included in the machine design to deliver accurate and high-quality cutting. These include support units for long workpiece materials to prevent sagging during the cut, a tilting laser head that enables highly accurate bevel cutting and an internal spatter guard that prevents burning to the internal workpiece surface. There are also options for a rotary tool spindle for tapping holes and thermal drilling.

The FT-150 FIBER is also equipped with automatic functions, including auto-profiler calibration and nozzle cleaning to further enhance productivity. Operator safety features were a high priority during the design of the machine, which features a fully enclosed cover that shields the cutting area and the internal loading and unloading area.

The laser processing machine is available in four different options, each with a 3.0 kW resonator, that can be specified depending upon the length of the workpiece material being machined, from 6,500 mm up to 8,000 mm.

TUBE DX

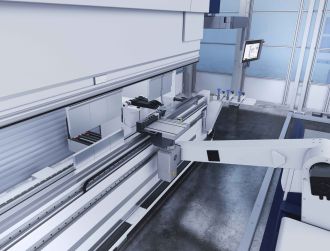

Mazak will also show for the first time in Europe the new CAD/CAM software, TUBE DX that has been developed to make programming and drawing import operations simple and fast. It integrates all the steps in the programming process, from CAD import to management of manufacturing orders, automatic nesting of the tubes and the creation of trajectories.

iCONNECT and Machine-2-Mazak

Mazak will also exhibit Mazak iCONNECT, a digital service for existing Mazak customers that has a suite of free services including product manuals and e-learning, along with a Machine-2-Mazak (M2M) subscription service. The M2M service enables increased machine monitoring, and proactive maintenance strategies – including remote support to detect problems – remote optimisation of machining processes with increased uptime and access to Mazak applications, project engineers and service operators.

Mr Gaetano Lo Guzzo, Director Laser Business Europe at Yamazaki Mazak, said: “The FT-150 FIBER with our new specialist tube CNC is the product of Mazak’s dedication to developing exceptional laser machines that use the latest technology and intelligent functions to drive speed, accuracy and, ultimately, profitability. We are excited to give a European debut to new SmoothTUBE CNC, which we believe is a step-change for tube cutting with an outstanding operator interface, easy-to-program and with all relevant machine information quickly available. We also look forward to talking to laser users about our industry-leading service and support capabilities that ensures your machines are in optimal condition to deliver high-quality cutting with minimal downtime.”