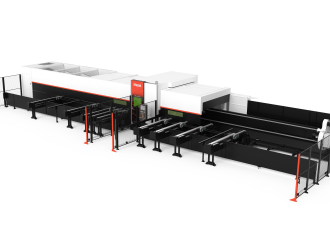

Yamazaki Mazak, a global leader in metal cutting machine tools and state-of-the-art manufacturing solutions, proudly introduces its latest innovation in 2D laser cutting machines – the OPTIPLEX Ez series. This new series includes two introductory models, the OPTIPLEX 3015 Ez and the OPTIPLEX 4220 Ez, designed to offer customers a user-friendly experience, affordability, and exceptional performance.

The OPTIPLEX Ez series enhances fiber laser cutting by seamlessly combining excellent cutting performance with straightforward maintenance. Designed for efficient cutting processes, these machines offer high mechanical rigidity, precision cutting, and unwavering reliability. Intelligent Functions empower users with efficient supportive and preventive measures, minimizing setup time for optimized productivity.

Entry-level laser cutting

The OPTIPLEX Ez is ideal for customers seeking a straightforward entry into laser cutting technology. The Mazak Ez series offers simplified functions which, combined with the integrated cutting database, make it suitable even for those venturing into this technology for the first time, providing a cost-effective and efficient solution.

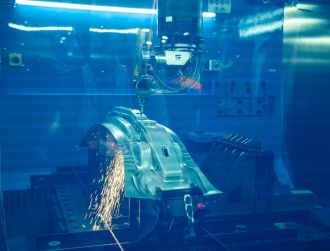

One of the standout features is the new Auto-Focus Torch and new fiber resonator, designed to enhance adaptability to various materials in the cutting process. The Torch's distinctive design facilitates quick, straightforward, and economical maintenance, as the protection window and lens can be swiftly replaced on-site, eliminating the need for specialist equipment. This is made possible by a specific cover that prevents any risk of contamination during the replacement process.

The OPTIPLEX Ez series utilizes a fiber laser source that results in low power consumption, streamlined maintenance and eliminates the requirement for laser gas. With configurations available in 3 kW, 4 kW, and 6 kW power options, the OPTIPLEX Ez machines are suited to diverse cutting requirements and can seamlessly integrate into automated systems for enhanced operational efficiency.

Space-efficient Design and Advanced Control

Large front and side sliding doors optimize floor space, ensuring hassle-free material loading and unloading. The tilting and rotating CNC control panel allows operators the flexibility to work at the front or side of the machine. The machine's robust cast iron structure guarantees stability and precision, minimizing susceptibility to deformation.

Equipped with the new MAZATROL SmoothLx CNC control, featuring a 21.5-inch display and a user-friendly Human Machine Interface, the Mazak OPTIPLEX Ez series provides intuitive operational functions making it accessible even for less experienced operators.

OPTIPLEX 4220 Ez: Expanding Possibilities

The OPTIPLEX 4220 Ez, with its substantial 2050x4120 mm working area, addresses the needs of users dealing with materials exceeding 4 meters. This model provides increased flexibility for a diverse range of applications, enhancing the series' versatility.

Both the OPTIPLEX 3015 Ez and OPTIPLEX 4220 Ez reflect Mazak's commitment to delivering reliable, efficient, and accessible solutions in laser cutting technology. The 3015 Ez model is on display at Mazak's European Laser Technology Center in Milan, offering Mazak customers the opportunity to witness live cutting demonstrations and experience firsthand the quality and benefits offered by this machine. The OPTIPLEX 3015 Ez will also be exhibited on the Mazak stand at EuroBLECH 2024, where it will be displayed with a new automation system.