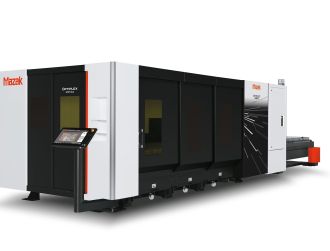

Mazak FG-400 NEO raises the bar of 3D tube laser cutting

Mazak continues to lead innovation with the release of a new model in the FG 3D laser cutting machine series. The FG-400 NEO is an all-in-one solution designed for maximum productivity and ease of operation. The new model is optimised for the high-speed processing of tubes, pipes, and long structural materials.

Featuring a Variable Beam Mode resonator, this latest machine design can incorporate multiple processes including 3D cutting, tapping, drilling, chamfering and flow-drilling. The Beam Shaping Technology controls where the power density of the laser beam is concentrated, improving the cutting speed and quality on a wide range of materials. The laser beam generated through the fiber has a shorter wavelength than CO2 technology and is, therefore, much more effective at metal cutting even on hard-to-process materials.

A wider array of possible applications

The FG-400 NEO has been specifically designed for cutting large-size tubes and pipes, such as round, square, and rectangular cross-sections, along with H, I, and L beams. The new model can also process highly reflective materials such as copper and brass and machine complex shapes and tight-fitting joints.

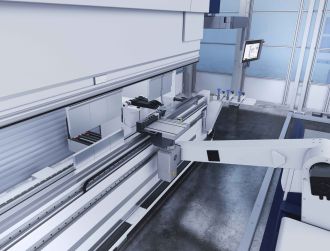

All of this is possible thanks to several cutting-edge features developed by Mazak to deliver superior cutting quality and accuracy. These include a 3D cutting head that can move in an A-axis and B-axis to enable the processing of a broader range of materials at the desired angle with a high level of accuracy. The 3D cutting head can also allow deflection to avoid damage in case of a collision with the workpiece. Four chucks work simultaneously, traveling along and rotating around the axes to prevent material distortion. This ensures a stable process on all thicknesses, resulting in an increase in productivity and a reduction in waste. Other features include auto centering and clamping of the material, as well as support units to accommodate different shapes and prevent material sagging during cutting. The machine is available with multiple configurations with loading/unloading units available in 6m, 8m, 12m and 15m.

Providing significant improvements, the FG-400 NEO enables faster cutting times with improvement of up to 33% on mild steel square pipes and H beam with oxygen assist gas, and up to 43% and 49% for mild steel and stainless steel square pipes respectively, when using nitrogen assist gas. The fiber resonator also provides a significant reduction in operating costs and environmental impact, with a reduction of up to 40% in electrical power consumption both during cutting and standby state. There is also no requirement for laser gas with Fiber Laser Technology.

Maximum accessibility and ease of operations

Mazak continues to focus on developing operator-friendly machines in terms of accessibility and ease of operation. The machine comes equipped with a 15” screen FX CNC and utilizes FX TUBE CAD/CAM software suite for pipe cutting, which offers a variety of features, including a nesting function, a simulation tool and a scheduling function for continuous production. Productivity benefits are gained through the combination of these elements which reduce setup times and the risk of human error.

The FG-400 NEO offers outstanding accessibility, excellent visibility of the cutting area and ease of use. The ergonomic design of the FG-400 NEO reduces the distance traveled by the operator during machine operation by positioning the operator panel, loading and unloading stations on the same side. This also provides the benefit of being able to position the machine against a factory wall to save space.

The exceptional productivity delivered by the fiber resonator, coupled with the capability to perform multiple processes on a single machine, makes the FG-400 NEO the ultimate solution for volume manufacturers aiming to take their tube processing capabilities to the next level.