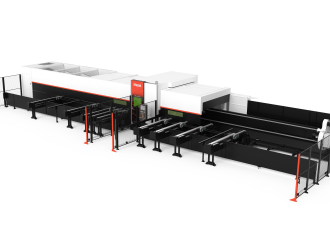

Mazak installs brand new cutting head in 2D Optiplex laser machine

Yamazaki Mazak has completed the development of a new 2D laser machine for top-notch sheet metal cutting operations. The brand-new Cutting Head MCT3 and the innovative Mazatrol SmoothLX CNC Control system are just a few of the technical standouts installed on the Optiplex 3015 NEO S-15.

The large working area allows processing workpieces up to 1525 mm x 3050 mm through a 15 kW fiber laser resonator. The unique Beam Shaping Technology automatically adjusts the beam diameter and energy concentration to ensure the best possible result on various materials and thicknesses.

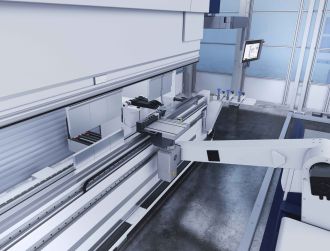

Automation is key

The newly-designed Cutting Head MCT3 boasts multiple intelligent functions to streamline the operator’s job even more: Auto Nozzle Changing to optimize laser cutting and reduce assist gas consumption, Auto Focus distance adjustment for faster cutting speeds, and Auto Calibration of the nozzle-workpiece distance drastically improve productivity.

Automating the overall setup time can lead to 95% quicker preparations compared to standard laser machines. Moreover, Intelligent Cutting functions such as Flash Cutting and Fine Power Ramping can enhance the overall process even more. Instead of stopping at each axis, the laser is turned on and off through Flash Cutting—synchronizing the axis and laser movements leads to greatly reduced cutting times. Fine Power Ramping is instead used to adjust the laser power and feed rate when cutting corners and straight lines to minimize dross without compromising the cutting speed.

Sensors everywhere

A wide assembly of sensors installed on the cutting head enables the Optiplex 3015 NEO S-15 to accurately monitor piercing and cutting operations and detect processing abnormalities and defects. For example, when plasma is detected, the Plasma Detection function adjusts the cutting speed to ensure good edge quality and minimize cutting imperfections. If instead burning occurs when cutting mid to thick mild steel plate, the Burn Detection function automatically stops the process to reduce failure. The Pierce Detection function detects when piercing has been completed and automatically begins the cutting process, reducing downtime considerably.

Optimal assistance to the machine operator

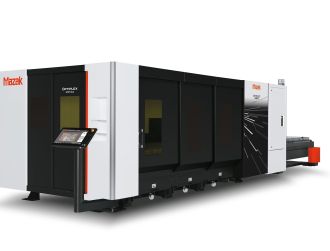

The Optiplex 3015 NEO S-15 has been specifically engineered to help operators in their daily work. Before the actual cutting takes place, Mazak Smart System can generate process data – thanks to two sets of cameras above the work area – to optimize sheet utilization in order to handle urgently required work and exploit the machine’s full potential. The new Mazatrol SmoothLX’s large 21.5” screen displays parts nesting at a glance, and the touch panel provides easy access to necessary information such as cut conditions or nozzle settings. Nest Programming, Cut Monitoring, Production Scheduling, and Machine Maintenance are just some of the many functions available to the operator. Also, the optional dual monitor allows multiple applications to run simultaneously.

Excellent Accessibility completes the picture. Large front and side access doors reduce the floor space needed and make material loading and unloading hassle-free; the tilting and rotating CNC control panel allows the operator to work at the front or at the side of the machine; the easily accessible work area enables direct control over the material while the nozzle centering camera allows <1 min adjustment times.