Hermle unites milling with Additive Manufacturing in "Sailing boat" project.

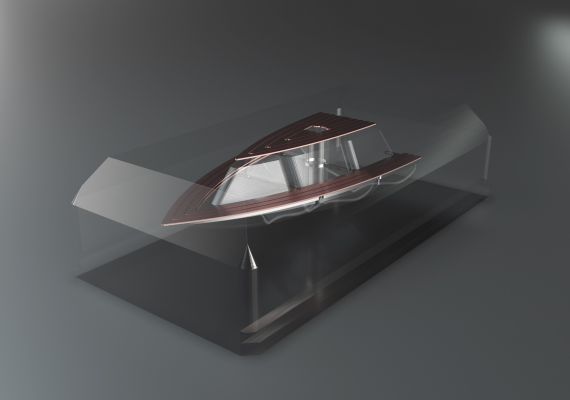

Additive machining with MPA technology and better milling all rolled into one. To give an impressive and somewhat striking example for a component produced by both Additive Manufacturing and subsequent machining to shape it, a sailing boat with a number of unique features was presented by Hermle in Gosheim, Germany.

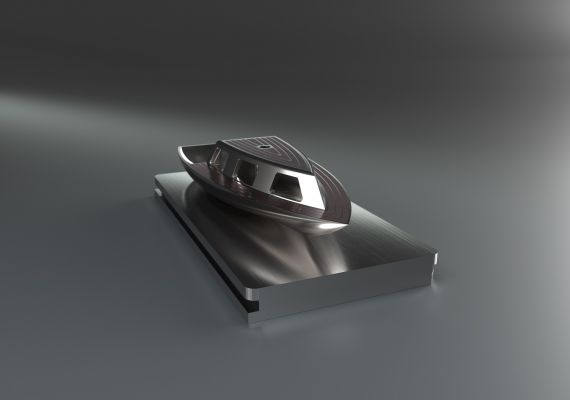

First, a blank (W x H x D 400 x 200 x 100 mm) was machined from 1.4404 by additive manufacturing via Hermle MPA technology. Due to the possibility of material combination, certain areas (deck and roof surface of the sailing boat) are made of pure copper and also integrated by additive manufacturing. Likewise, a large hollow space (cabin) was generated by means of water-soluble filler material. Via the subsequent processing, the copper surfaces were milled free again and the windows were milled into the cabin so that you can see its interior. The hull of the boat is realised in classic 5-axis simultaneous machining. Here, the 1.4404 material was quite challenging for the tools used and the selected milling strategy.

Machining delicate shapes

The sail with the mast was manufactured classically in aluminium in a separate machining process; due to its delicate shape, it also proved to be a complex task for the programming department. Using the programming system Tebis, they found an optimum solution. Then, the hull was connected to the mast and sail using conventional pinned fittings. In the Hermle premises, the finished sailing boat will symbolically represent the two technologies of additive manufacturing and 5-axis milling – all from a single source.