HELLER’s fourth generation of the 4-axis horizontal machining centres has arrived

In February 2021, the fourth generation of the H series was launched. The 4-axis horizontal machining centres offer numerous benefits over the previous generation and stand out even more from other machines in this segment: with shorter idle times, increased milling performance, reduced service times and more flexible customization to customers’ requirements.

HELLER has been known as a specialist in 4-axis machining centres since the 1960s. With the H series (H for horizontal) presented in 2007, the company then launched a machine tool that is considered the benchmark by users from many industries. In particular, manufacturers and suppliers from the broad industrial sector (among them machine builders, contract manufacturers, energy and fluid technology companies) but also companies from the automotive sector are using the 4-axis horizontal machines for the production of medium to large volumes.

In spring 2020, the first machines of the fourth generation were put into field test operation at selected customers. Dr. Manuel Gerst, HELLER Head of Development, explains: “Our goal was to put the H series through rigorous testing under real-life conditions in order to launch a mature machine to the market at the beginning of 2021.”

Chip-to-chip times reduced by up to 15 percent

Mission accomplished. Since February 2021, HELLER has been offering the horizontal machining centres in the sizes H 2000, H 4000, H 5000 and H 6000, covering a stroke range from 630 mm to 1,000 mm: the first two models for tools with HSK-A 63, the larger ones with HSK-A 100. With a construction in modular design and many standard components, users have a wide range of options to adapt the machine to their individual requirements. In terms of drive technology, there are essentially two equipment packages to choose from: Power and Speed. The Power package has been designed for medium batch sizes and for the machining of steel and difficult-to-machine materials. The Speed package is suited for high-volume machining of cast iron, aluminium and other light metals.

In order to achieve optimum productivity in combination with the necessary precision for each application, Manuel Gerst and his team focused on a range of aspects. One of the most important ones he states is the reduction of idle times. Expressed in figures: “With the Speed equipment package for the Gen4 we have succeeded in reducing chip-to-chip times by an average of 10 percent,” says the Head of Development, adding: “One of the crucial factors are the short positioning times. In field tests, we were also able to demonstrate cycle time improvements of approx. 7 percent.”

What has also proved helpful is the new AutoSet technology cycle for weight-dependent dynamics adjustment of the Z-axis and B-axis included in the Speed equipment package. The cycle helps to achieve the optimum axis dynamics in direct correlation to the load capacity. Moreover, the developers have optimised the tool change process in order to enable time savings for medium tool weights and have reduced the spindle run-up times. Depending on spindle size, these vary between approx. 1.4 and 2.6 seconds.

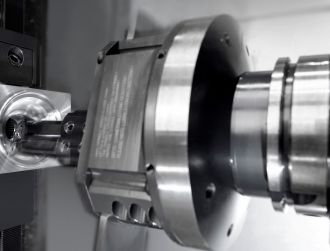

HELLER inline spindle for Gen4 in three versions

At the same time, the Nürtingen-based machine tool manufacturer succeeded in further improving the machining times of its fourth-generation H series. According to Gerst, the heart of the machine – the spindle – played the decisive role in this success. The in-house developed spindle for the Gen4 machines is available in three different versions: Power (PC), Speed (SC) and a new Dynamic Cutting (DC) version. All spindles are available with HSK-A 63 or HSK-A 100 tool holder. The DC units in particular offer a perfect combination of high torques and high speeds – with the DC 63 i version providing 16,000 rpm and 180 Nm and the DC 100 i option delivering 12,000 rpm and 400 Nm. “Users requiring even higher torques can still opt for our classic gear-driven spindles found on models H 5000 and H 6000 which are available with up to 2,292 Nm torque,” adds Gerst.

However, the high spindle power and the extreme axis dynamics alone are not sufficient to increase the machine’s productivity in practical application. To achieve this, the machine also has to provide the necessary stability and a suitable damping behavior. Therefore, the classic machine design with a twin drive in the Z-axis has been maintained and improved with regard to numerous details.

High-Accuracy package and U-axis

Thanks to a substantial number of innovations, the machines from the H series already provide high basic accuracy and surface finishes. In combination with the optional High-Accuracy package, a further improvement in these two regards can be achieved. Moreover, even potential temperature fluctuations can be compensated in a quick and easy way. With the touch of a few buttons, the two ‘AutoCal’ und ‘AutoLin’ software features allow adjusting the axis geometry to the current conditions within a few minutes.

Furthermore, the integrable U-axis of the HELLER out-facing head allows users to perform contour turning operations on their components using motion tools. According to HELLER Head of Sales Fabian Mattes, the feature is a frequently requested option. He adds: “In series production, it eliminates the otherwise necessary changeover to a turning machine, resulting in massive time, and thus, cost savings.”

Reduced life-cycle costs

What also saves users hard cash are the reduced life-cycle costs. The HELLER machines achieve this in different ways. For example, the developers succeeded in reducing the energy consumption of the new H series. Speed-controlled pumps in the hydraulic unit and in the high-pressure portion of the coolant unit, smart switch-off strategies of energy consumers and the use of machine waste heat by optional water/water heat exchangers and many other features ensure low energy consumption.

Another important aspect: maintenance and service work can now be performed even faster. The key to this is good accessibility to all units. As an example, Fabian Mattes mentions easy spindle replacement based on the HELLER zero-spindle system – one of the service highlights, as he says: “Our zero spindles can be exchanged within about an hour as only the mechanical parts have to be replaced. The motor remains inside. As a result, our customers are able to save approx. 30 percent of running costs throughout the life cycle of a spindle compared to classic motor spindles. With the reduced downtimes not even counted in.”

According to Mattes, the field-test customers also praised the new, clearly arranged user concept. The main operating unit in panel design with a double pivot arm is installed next to the work area door equipped with a large vision panel. This allows the operator to keep an eye on both the screen and the work area. Another useful feature when running in processes is the WorkCam work area camera. It allows the user to monitor processes throughout the entire work area on the 24” screen. Multi-touch technology as well as additional hardkeys and three potentiometers for the regulation of speed, feed and rapid traverse provide increased operational convenience and simplify setup and operation of the machine.

Improved ergonomics

In addition to the operating unit, HELLER also enhanced other working areas of the operator with a focus on ergonomics –visually and practically. A compact, touch-sensitive operating panel comprising key functions, the low loading sill, short overhangs and the possibility of overhead loading make work at the workpiece setting station easier. Integrated LED lighting at the setting stations and inside the work area are standard.

Not new, but significantly enhanced, and opted for by more than 80 percent of H series buyers, is the wide range of Industry 4.0 features available from HELLER under the product name HELLER4Industry (see box). All these HELLER4Industry features can be visualised directly at the machine, in the company network or online. Connectivity to MES and ERP systems has been expanded by OPC UA-based communication with the help of ‘umati’, simplifying the integration into the company network. Users, who also use the HELLER Services Interface (HSI) option, are provided secure access to their production and maintenance data from any location in the form of a browser-based solution.