Heller Introduced Compact 5-Axis Milling Machine for Next Generation Machinists

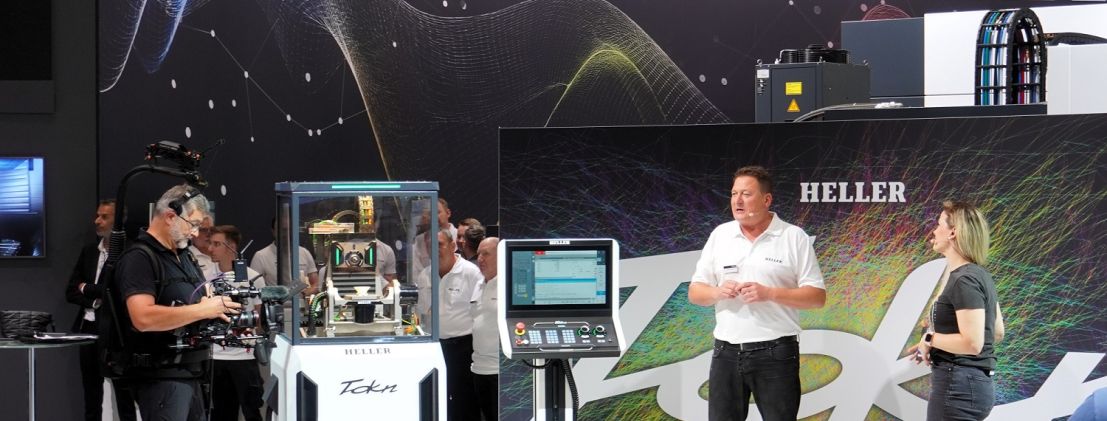

New machining centers, automation systems and digital solutions were secondary issues for Heller at the AMB in Stuttgart last September. The machine builder put the spotlight entirely on the introduction of the Tokn. This compact, 5-axis milling machine is designed to inspire and train the new generation of machinists. It is equipped with state-of-the-art components to get the young generation excited about modern machining.

During the AMB, the new was unveiled for the first time at the Heller stand. There was a lot of interest in the unveiling. When the curtain was lifted, a large audience saw the new machine in person for the first time. The very compact construction with a floor space of about one square meter combined with the modern design caught the eye first. However, it does not stop at a modern look. In fact, the Tokn is equipped with high-end components.

Thorsten Schmidt, CEO of Heller underlined during the press conference the necessity of training new professionals. “Heller has an extensive apprenticeship program to introduce young people to engineering and to train them to become true professionals. To get the new generation excited, they must work with modern technologies from the beginning that immediately show how clean and high-tech production technology is today. For this reason, we have developed a 5-axis machine specifically for training institutions and apprenticeships. Students must be prepared for contemporary machining during their training. This means that they must learn to work with modern controls and complex workpiece forms. The Tokn was developed especially for this purpose. In addition to the latest components, the machine is equipped with 5-axis, so students can already learn to think in complete machining right away.”

High-end parts

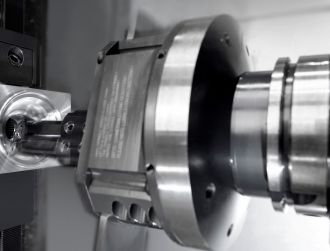

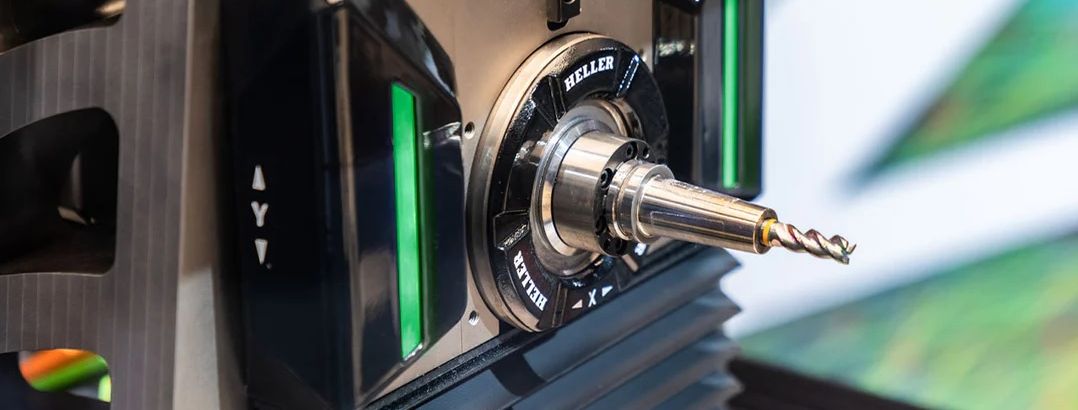

Indeed, a look at the Tokn shows that no savings have been made on the components. For example, the machine is equipped with the latest Siemens SINUMERIK ONE control that is mobile and adjustable. This control provides students with the opportunity to work with technology that is also used in industry, enhancing their learning experience. Furthermore, the Heller Tokn was designed with exceptional versatility in mind, thanks in part to the 200 mm stroke it offers. This translates to wide applicability for various machining operations, allowing students to learn to handle a range of machining processes and workpieces. The machine is capable of performing movements at speeds of up to 15 meters per minute. This high speed ensures efficient and dynamic machining operations.

Also of interest is the integrated swiveling table. The A-axis of this table can tilt from +30° to -120°, while the B-axis allows full 360° rotation. This allows students to experiment with complex workpiece configurations and machining techniques. For the spindle, Heller has chosen a variant with a maximum torque of 2.75 Nm and a speed of up to 9,000 min-1. Another important aspect of the Tokn is the integrated lighting and tool storage. The well-lit work area ensures optimum visibility, which improves safety and accuracy during the machining process. In addition, the integrated tool storage ensures that tool changes are smooth and easy, significantly improving workflow.

Finally, the Heller Tokn is distinguished by its fully mobile plug-and-play construction. This feature allows the machine to be easily moved and used immediately without complex installation procedures. For training institutions with limited space or where setups change frequently, this is an ideal solution.