Grinding Solution Park Science Unites Top Five German Research Institutes at GrindingHub

Five production technology research institutes will be showcasing their current grinding technology projects at GrindingHub, which takes place in Stuttgart from May 14 to 17. They can be found at the Grinding Solution Park Science in Hall 10 and represent the who's who of grinding technology research in Germany.

The IFW (Institute of Production Engineering and Machine Tools) at Leibniz University Hanover, inspire AG, Zürich, the ISF (Institute of Machining Technology) at TU Dortmund University, the IWF (Institute of Machine Tools and Factory Management) at TU Berlin and the MTI (Manufacturing Technology Institute) at RWTH Aachen University are taking part. "GrindingHub is an ideal meeting place to exchange ideas about innovations and developments in grinding technology and to help shape the future of the industry," says Prof. Dirk Biermann, Head of the ISF at the Technical University of Dortmund.

From research to industrial application

An important concern of the university institutes is networking with the industry. "We use knowledge and experience from decades of research to support companies from the cylindrical, surface/profile, tool and vibratory grinding sectors with their individual challenges," says Peter Breuer, Group Leader Grinding Technology at the MTI of RWTH Aachen University, describing the aim of his participation. A large number of companies from the application, machine and grinding tool and cooling lubricant sectors are involved in the respective research projects of the institutes and thus make a significant contribution to advancing the investigations. Projects and highlights from basic research will be presented in order to provide an in-depth understanding of the interdependencies in grinding and finishing. Here, companies have the opportunity to discuss production-related issues with a comprehensive industry network. The aim is to transfer the knowledge gained quickly and effectively into industrial applications.

Focus on current trends

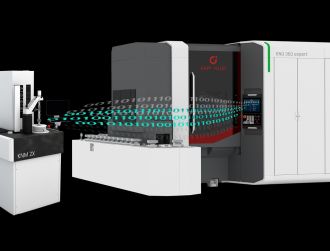

All participating research institutes and companies are dedicated to grinding technology topics that move the industry. These include, for example, studies into the machining of new and innovative materials or grinding processes to produce tribologically effective surfaces. The focus is on process reliability (first part right) as well as predictive modeling and machine learning models. At the same time, the focus is on sustainable production, digital process integration and innovative tool concepts for precision surface finishing. "In production technology, it is up to us to drive forward the development of resource-friendly processes. The grinding process in particular requires a considerable amount of energy due to its peripheral equipment. We therefore conduct holistic research that focuses on minimizing the consumption of energy and resources, from the manufacture of the grinding tools through to their use," says Prof. Berend Denkena, Head of the IFW at Leibniz University Hanover. Visitors to the Grinding Solution Park Science can look forward to a wide range of exhibits. The exhibits will include sensorized tool holders for bore grinding under high-speed conditions, additively manufactured grinding tools with a three-dimensional profile, generating grinding tools for milling cutter production and diamond grinding tools with graded grain concentration.

"It is important to us to represent the entire production environment at GrindingHub as the industry meeting place for grinding technology. Synergies between research and industry play a central role here. Visitors can experience this live and on site at the Grinding Solution Park Science," concludes Dr. Marcus Heering, Managing Director of GrindingHub organizer VDW (German Machine Tool Builders' Association).