Hard-coated Brake Disks are a Stress Test for Grinding

Traffic gives rise to high levels of particulate emissions – especially in the cities. Too high, in the opinion of the EU Commission, which is pushing for significant reductions by introducing the Euro 7 emissions standard. Particulate emissions are caused primarily by abrasion in tires and brakes. An effective way to combat the emissions is therefore to use hard-coated brake discs which can reduce abrasion by up to 90 percent.

However, manufacturing them poses special challenges for the grinding technology involved. The considerable time pressure being imposed by the new laws is making it particularly important to ensure that the process design and the resulting development partnerships are effectively coordinated. Nevertheless, this stress test for the sector could ultimately prove advantageous, particularly now that investment is shifting towards electric vehicles.

At the latest ‘Schleiftagung’ grinding conference in Stuttgart-Fellbach, Prof. Eckart Uhlmann from the Institute of Machine Tools and Factory Management IWF at TU Berlin underlined the impact of the energy and mobility transition on production and manufacturing technologies – including grinding. The conference is a high-caliber event organized by the WGP, the German Academic Association for Production Technology. Components such as electric motors, low-emission brake systems and high-efficiency, low-noise gearboxes in electrically powered vehicles must be manufactured in a time-efficient and quality-assured manner, in line with the exacting requirements for economic and ecological sustainability. Uhlmann, a further member of the WGP, warned that this can only succeed if the full optimization potential of grinding technology is exploited. Hard-coated brake disks represent a good example of this. It is also one of the trending topics at the upcoming GrindingHub, being organized by the VDW (German Machine Tool Builders' Association) in Stuttgart from 14 to 17 May 2024.

New materials increase complexity

Jannik Röttger explains the particular challenges involved in machining hard-coated brake discs. This September, he moved from a research position at RWTH Aachen University to Salach in southwest Germany as the new Head of Grinding Technology at Emag Maschinenfabrik: "Put simply, what hard-coated brake discs do in the grinding machine is exactly the same as what they do in a low-emission vehicle – create a powerful braking effect with no loss of material," says Röttger. "However, we need to achieve the exact opposite in the grinding process. The aim is to remove material in the shortest possible time in order to create the required geometry and surface properties."

As the grinding expert explains, the hard coating consists of a relatively soft matrix, with carbides serving as the hard material. Both materials have fundamentally different machining properties. As a rule, grinding tools are optimized for either one or the other material behaviour. The new material makes the development of suitable grinding disks a major challenge. It is very complex to design the static and dynamic machine properties and the spindle drives due to the process forces involved.

Furthermore, it is not only the volumetric composition of the hard material and matrix that influences the machining properties of the hard material layer, but also the coating process.

For laser deposition welding, for example, Röttger cites process parameters such as laser power and relative speeds. The thermal energy of the laser could cause the brake disk to distort. This must be taken into account in the subsequent grinding process. For this reason, the entire process chain after the casting of the unmachined part – i.e. turning, laser coating and grinding as well as the resulting functional properties in the vehicle – must be considered and optimized as an overall system.

Manufacturing solutions for the entire processing chain

The Emag Group, which is exhibiting at GrindingHub, says it offers manufacturing solutions for each individual link in the machining chain after the casting process. This allows it to assess the specific interactions between the different manufacturing processes on its own turning, laser and grinding machines. According to Jannik Röttger, the designers, production engineers and materials scientists work together in an interdisciplinary team in research and development to understand the cause-and-effect relationships between the setting and result parameters. External experts, such as scientists from RWTH Aachen University and coating system developers from HPL Technology, a start-up from RWTH Aachen University, are also involved.

Michael Wöhrle, Head of Research and Development at Supfina Grieshaber, Wolfach, is also convinced of the benefits of interdisciplinary and cross-company collaboration. The company started developing processes for grinding hard-coated brake discs back in 2019. "From the outset, we have felt that close cooperation with our development partners is the only way to meet the EU’s Euro 7 requirements within the required timeframe," says Wöhrle. "We had to feel our way into the process – see what the powder manufacturers could bring to the table, for example, consider what the different coating processes involve, and ultimately decide what is realistic and what can be ruled out because it is simply too expensive for the mass market."

Supfina is not ruling out any technologies, but is focusing primarily on laser deposition welding and the cold spray process. In the beginning, they were meeting with the coating specialists almost every week. "We’re seeing an unprecedented pace of innovation," says Wöhrle. However, the constant uncertainty as to whether the government will make changes – and what these could be – is seen as burdensome. Wöhrle nevertheless considers the reduction of particulate matter pollution to be absolutely essential, both for human health and for the environment. He also concedes: "Without the new regulations, we wouldn't be as far along as we are now."

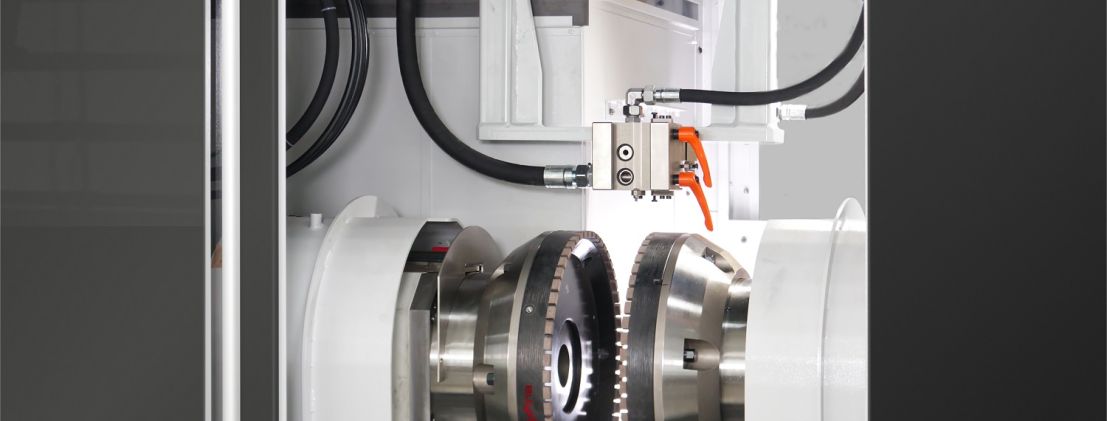

Double-sided grinding for economical machining

Almost 100 million brake discs are produced in Europe every year; around half of these are sold to vehicle manufacturers, while the other half is destined for the spare parts market. Experts assume that the vehicle industry will need to invest billions to produce brake disks which reduce fine dust levels and are eco-friendly. "Until recently, some brake discs were so cheap that they were sold by the tonne," says Michael Wöhrle. "Expensive raw materials and processes have now been added to the mix, and with them the challenge of developing a product suitable for the mass market." Double-sided grinding is favoured by machine manufacturers because, according to Wöhrle, it guarantees simultaneous machining of both friction ring surfaces, high throughput rates and short cycle times. Supfina recently unveiled a new machine, the Planet BD, which is already being used by a number of well-known customers. As Michael Wöhrle points out, this is a grinding machine that was developed for a single product, namely the brake disc of the future.

This type of machine will then also be used to machine brake discs for electric cars. The brakes are applied far less frequently in purely electric vehicles, and with less force, because the recuperation of the motor often provides sufficient braking power. This carries the risk, however, of the "underused" brake system starting to rust, especially in wet weather conditions. Coated brake discs can help solve this problem, too. Supfina's Head of Development Michael Wöhrle is confident that the coating can be adapted to the slightly lower requirements in terms of braking performance and number of braking cycles. The quantity of expensive components in the coatings can be reduced or replaced, resulting in a system which is somewhat more cost-effective, albeit with slightly reduced performance. The experience gained in passing the Euro 7 stress test will ensure that the grinding experts are well prepared to achieve this.