DN Solutions enters the 3D metal printing market with DLX series

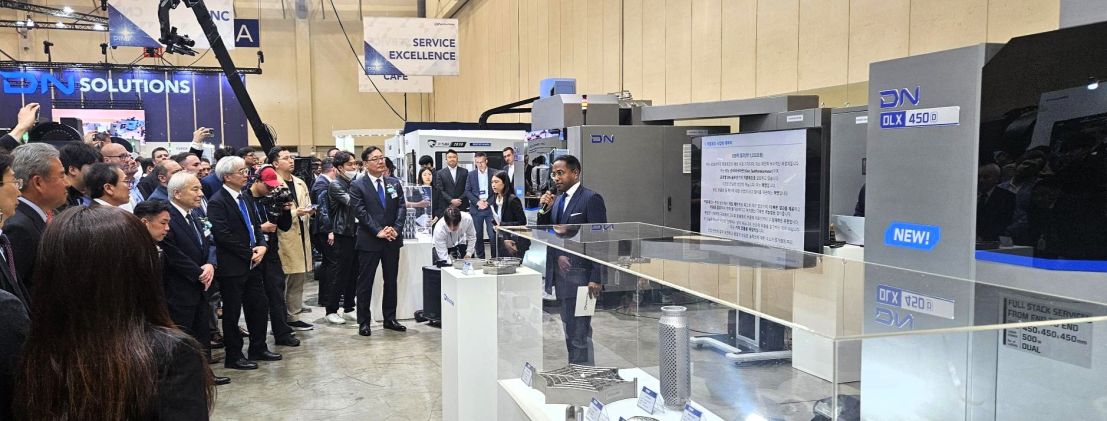

During the DN Solutions International Machine Tool Fair (DIMF) 2025, DN Solutions unveiled its new DLX series of 3D metal printers. With this launch, the South Korean machine tool manufacturer officially marks its entry into the industrial Laser Powder Bed Fusion (LPBF) market.

The fifteenth edition of the DIMF event was held under the theme “Automation Solutions Platform for All Machining Processes” and attracted over 5,000 visitors, including 1,000 international partners and customers. The exhibition featured over fifty next-generation machining systems, automation solutions, and smart software applications. For the first time, additive manufacturing (AM) also took a prominent role, expanding DN Solutions’ technological scope.

Laser Powder Bed Fusion

The launch of the DLX series was the highlight of the exhibition. These are DN Solutions’ first industrial-grade LPBF systems. During the event, the DLX 450 was demonstrated live. The machine is capable of producing complex metal components up to dimensions of 450 mm × 450 mm × 450 mm (X×Y×Z). A variety of materials can be used, including aluminum alloys, Inconel, and titanium. The printer supports configurations with one to four fiber lasers, ranging from 500 W to 1 kW. Depending on the application, layer thicknesses between 30 and 90 microns can be achieved, with a maximum build speed of 20 cm³ per hour.

Integrated Software

The DLX series includes an internally developed software package for additive manufacturing. This platform supports a complete workflow tailored to the industrial application of metal printing. It enables users to identify AM-suitable parts and estimate per-part production costs. Furthermore, it provides tools for designing and optimizing support structures, simulating deformation during printing, and applying compensations to correct it. Users can also develop new material processing parameters and improve quality when using existing materials. This integrated approach is designed to deliver high precision, repeatability, and smooth integration of metal AM into existing manufacturing environments.

To validate the technology in practice, DN Solutions redesigned a spindle cylinder front cap of a multitasking machine using Design for Additive Manufacturing (DfAM) principles. The result was a 20% performance improvement, made possible by a more efficient internal structure and simplified assembly.

Additive Manufacturing Solution Center

Coinciding with the launch of the DLX series, DN Solutions announced the opening of its first Additive Manufacturing Solution Center (ASC) in Germany. This facility will serve as a hub for AM part design, process optimization, prototyping, and production. Similar centers are planned for South Korea and the United States.

According to CEO Wonjong Kim, the time for waiting is over. “Additive manufacturing is no longer something of the future—it is ready for large-scale application today,” he stated. “By combining this technology with our expertise in machining and automation, we are building a complete manufacturing platform for the next generation.”