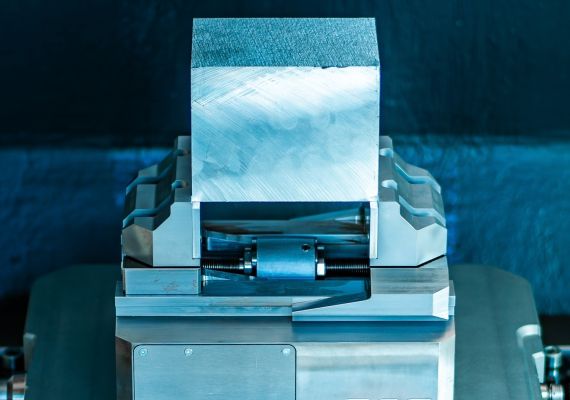

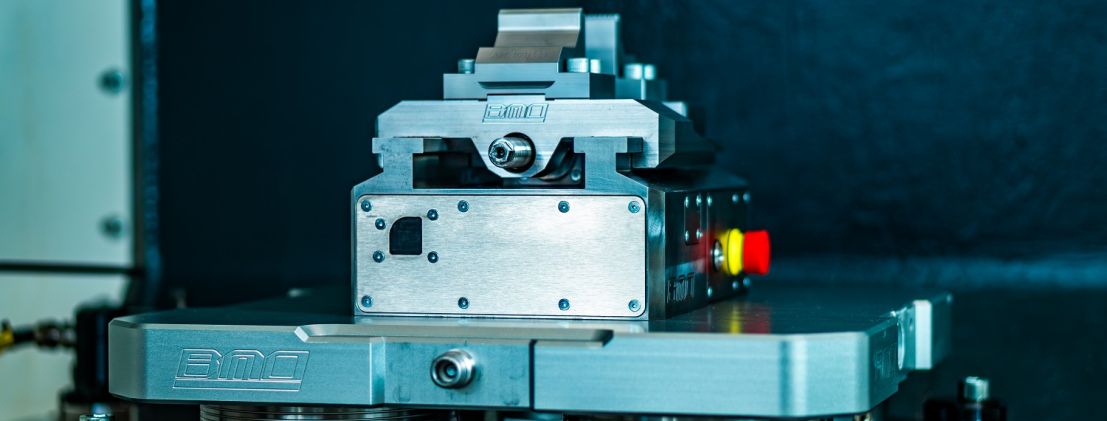

BMO OptiVice Self-adjusting Vice for Autonomous Machining

In the autonomous factory of the future, CNC machines will configure themselves for the product to be machined. BMO Automation is already making this possible with the new OptiVice, which reduces the set-up time for a different product to zero. This is possible because this new, electric vice adjusts itself to the material to be machined.

The OptiVice's stroke is 130 mm, providing a clamping range of 0 to 130 or 90 to 220 mm. The vice draws power from an integrated battery. This allows the vice to be placed on any machine, regardless of whether it has preparations for automation, such as a feed-through in the 5-axis machine table.

Unmanned production of small batches and single pieces

CEO Frank Biemans explaines: ‘With this OptiVice we reduce set-up time to zero which is great for companies who manufacture small batches or even single pieces in unmanned hours. They can switch between producing various batches without the need for extra pallets with vices and without changing vices.’ The chance of an incorrect setting by the operator is also reduced to zero. If the vice does not reach the required clamping force for any reason, during the day a warning is provided and at night the next production task starts automatically. The OptiVice has an open construction. Practical tests show that this does not cause any problems with chips getting stuck in its parts.

Biemans: ‘Because we make use of an open system, we can use the machine's cooling lubrication system to rinse the vice clean. You configure how often this should be done in the software.’ With the OptiVice automatic vice, BMO Automation further reduces set-up time. This is especially noticeable in small series, where most of the lost time is spent changing vices or clamping jaws.

OptiVice is one of BMO’s building blocks for an autonomous factory. Recently the company also introduced Infinity, a new CNC automation platform for autonomous machining.