BMO Automation Developed New CNC Automation Platform for Autonomous Machining

BMO Automation introduced a completely new CNC automation platform: Infinity. The modular platform consists of a robot module and a dynamic storage system. It provides machining companies with solutions for more efficient deployment of scarce CNC operators, leading to higher CNC machine utilisation rates. ‘We provide the building blocks with which machining companies can start creating an autonomous factory today,’ says founder and CEO Frank Biemans.

In the machining industry, the fully autonomous factory is still just a dream. Biemans does not expect that many companies will ever take the step of building such a factory from scratch. ‘The autonomous factory is not a project but rather a process in which you take incremental steps towards the final goal,’ he says. This makes it even more important that when a company invests in automation today those solutions will still be usable in the autonomous factory of the future. This is precisely the essence of the Infinity Platform.

Dynamic storage

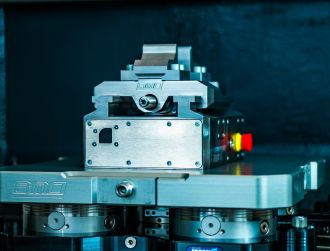

At the heart of the new Infinity platform is a standardised robot module (Yaskawa 50, 88, 180 or 225 kg), control hub, and storage area: the next-generation robot cell. The robot module has space for forty 600 x 400 mm carriers, and can be expanded with storage modules for 400 x 600, 600 x 600 or 800 x 600 mm trays. These can be used to store materials, workpieces, vices, jaws, robot grippers, crates... you name it. The Infinity even has room for storage on a euro pallet.

The BMO software controlling the cell automatically determines the distance between two carriers in the rack, depending on what is on the tray. Algorithms continuously evaluate the most ideal arrangement. Dynamic storage is essential because machining companies make products of different sizes every week.

BMO Automation intentionally puts all the intelligence into the robot and software, not the hardware itself. Frank Biemans: ‘Any actuator or sensor can cause a failure. In our system, the robot is essentially the actuator; the robot places the carrier containing the raw material, machined product, pallets or fixture tools in the rack. Because the software controls everything, you have maximum storage flexibility. And because we choose the reliable Yaskawa industrial robots, the system is robust and fault tolerant.’ This keeps the total cost of ownership low, which has a direct effect on the hourly rate. Moreover, a user can expand the number of carrier positions on a modular basis when there is a need for more storage capacity— and at any future time as well, so the system can grow with the company. BMO offers a range of flexible solutions for this.

In addition, the Infinity platform is prepared for the integration of an AMR (Autonomous Mobile Robot) as standard, and you can expand the Infinity platform with a handcart docking module. These handcarts are then unloaded by the same robot.

Job differentiation

With its Infinity platform, BMO is also taking the first step towards job differentiation in machining. Frank Biemans argues for a distinction between logistics tasks and work for which you really need machining knowledge. He wants to eliminate the many hours a CNC operator now spends loading the robot cell and removing all the products the next day. This is why BMO Automation is introducing the supply chain crate. This standardised crate, widely used in the automotive industry, holds the product carriers. These crates are placed in the Infinity cell via the set-up module or the AMR docking module, after which the robot places the crates in the correct location in the dynamic storage.

Biemans: ‘The idea is that the crate is filled in the in-house sawing department or at the material supplier and then placed in the robot cell in its entirety. This eliminates the need for staff to spend half a day placing raw material in the cell and then removing the processed products.’ After all, the robot can also put the parts back in the same crate or another crate. For high-quality or scratch-prone workpieces, for example, the robot can also place them in a crate with foam protection to prevent damage. BMO Automation calls this crate the ‘supply chain crate’ because it can go through the entire chain. In other words, the crate containing the machined components can be delivered to the customer or the next step in the chain.