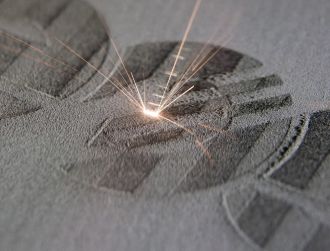

ZEISS and EOS launch advanced powder bed analysis solution

ZEISS and EOS have jointly developed and launched an advanced in-process and post-print powder bed analysis solution. Using a patented technology from ZEISS, all features of the powder bed are captured with high precision for thorough, reliable analysis layer-by-layer and evaluation of the entire print job. This provides a performant in-situ-proof of powder bed quality via images and defect statistics instead of after-build testing of parts.

ZEISS AM in-process offers rapid defect detection and classification with an ultra-high resolution per pixel. A reliable revealing of irregularities in powder bed, even with strongly reflecting materials, is ensured by combining four illumination directions.

The classification allows preventive and corrective measures to be implemented for specific powder bed defects. Thus, faulty jobs can be stopped early to save productive machine time and improve material usage. Powder shortages can even be corrected as they arise due to a communication interface that enables automatic recoating on the build plate. As part of the cooperation, ZEISS AM in-process will be integrated into EOS DMLS systems. The technology will be available for the EOS M 290 systems, both for already installed and new machines, with no parametrization required for different materials and geometries and without impact on the gas flow.