EOS developed four new metals for Additive Manufacturing (AM)

EOS has announced the introduction of four new metal materials for additive manufacturing (AM) on the EOS M 290 metal system, including two stainless steels, one tool steel and one nickel alloy. These four new metal materials were designed and optimized specifically to the needs of additive manufacturing. EOS is increasing application opportunities for demanding industries by bringing AM-tailored alloys to its customers.

EOS StainlessSteel 254 for extreme conditions

The first new material from EOS is StainlessSteel 254. This is an austenitic stainless steel that comes with a 40/60 µm process for the EOS M 290 system. The high chromium, molybdenum and nitrogen alloying give excellent corrosion resistance in many difficult environments. The material has an excellent stress corrosion cracking and higher strength than conventional austenitic steel. It also shows excellent resistance to uniform, pitting and crevice corrosion. The material is particularly suited for applications such as chlorinated seawater handling equipment, pulp, and paper manufacturing devices as well as chemical handling equipment.

EOS StainlessSteel SuperDuplex

For difficult environments, EOS developed the new StainlessSteel SuperDuplex material. This is an austenitic-ferritic duplex stainless steel optimized for additive manufacturing while maintaining super duplex properties. The material comes with a 40/80 µm process for the EOS M 290 system. Its high chromium, molybdenum and nitrogen alloying give excellent corrosion resistance in many difficult environments. At the same time, it shows excellent resistance to uniform, pitting and crevice corrosion, as well as enabling high strength together with high corrosion resistance. The optimization of phase balance enables use of the product in a manufactured condition in many use cases. The material is particularly suited for applications in the oil and gas industry, in pulp and paper manufacturing devices and for mining and offshore equipment.

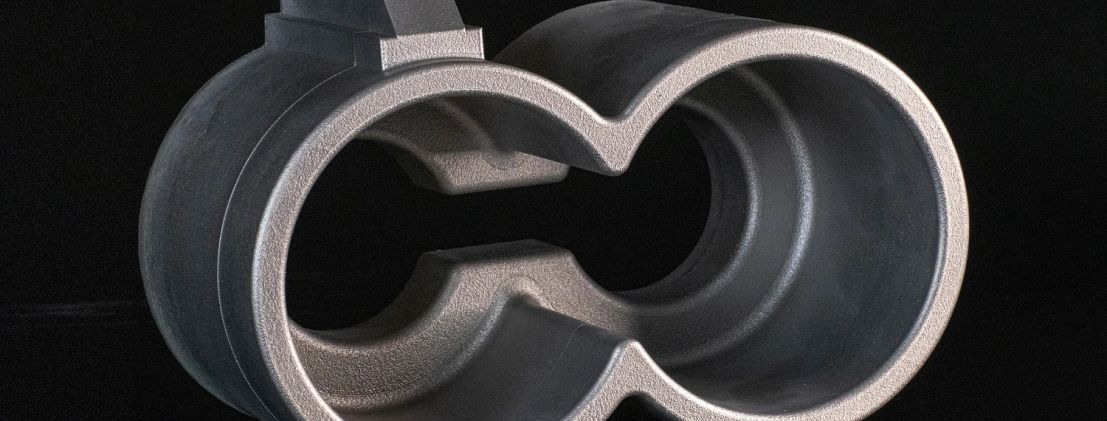

EOS ToolSteel CM55

For use in elevated temperatures. EOS introduced ToolSteel CM55. This new material comes with a 40/80 µm process for the EOS M 290 system. It is a cobalt-free, ultra-high strength, and high hardness steel for tooling and engineering solutions. Its alloying elements and moderate carbon content form a strong and stable structure for demanding applications and for the use in elevated temperatures. Typical applications are cold and hot working tools, powertrain components and parts for mechanical engineering.

EOS NickelAlloy HAYNES 282

For use at elevated temperatures EOS offers the new material NickelAlloy HAYNES 282. This is a nickel alloy powder intended for manufacturing parts on EOS metal systems. It is a precipitation-strengthened nickel-base superalloy with a unique combination of high-temperature strength, thermal stability, good corrosion, and oxidation resistance, easy fabricability and excellent weldability. It was developed for high-temperature structural applications and is manufactured under license from Haynes International. Typical applications range from aerospace and rocket engine components to turbomachinery and gas turbine parts, and to energy industry components.

TRL 3 Core materials

EOS uses an approach that is unique in the AM industry, taking each of the three central technical elements of the production process into account: the system, the material, and the process. The data resulting from each combination is assigned a Technology Readiness Level (TRL) which makes the expected performance and production capability of the solution transparent. EOS incorporates these TRLs into two categories: premium products (TRL 7-9) offer highly validated data, proven capability, and reproducible part properties. Core products (TRL 3 and 5) enable early customer access to the newest technology still under development and are therefore less mature with less data. All of the above materials have a TRL 3 Core classification.