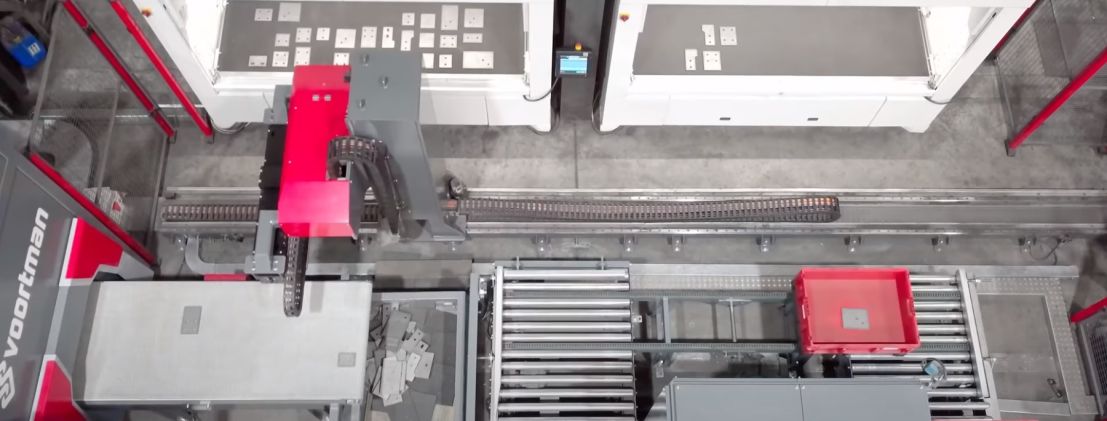

The days of sorting plate parts are over with the Voortman Plate Sorter

The new Voortman Plate Sorter will change the entire logistical routing of plate parts to the welding area, with maximum efficiency as a result. The days of sorting plate parts at the machine, missing parts at the welding area, and complete chaos at the plate and welding area are over.

Multiple phases and projects can be nested together in one plate, increasing your efficiency and reducing your material costs. Is the whole plate processed? Simply unload the finished parts from the cutting table, put them unsorted in a bin and move it to the Voortman Plate Sorter. It will do the rest! It scans and identifies the plates, checks their quality, sorts them into the right bin and stores them in a storage tower. It's that easy!

Create ready parts

Optimizing and streamlining logistic processes also is a core part of the multi-processing philosophy from Voortman. The multi-processing machines create a cost-efficient, flexible and streamlined production process. There's no need for moving or dividing material across different workstations anymore, resulting in less transport and intermediate stock in your workshop.

For instance, the Voortman V633 enables you to simultaneously drill holes and mark, but also mill up to a diameter of 20 mm in one powerful pass, all on one single machine! Additionally, the new pipe-cutting unit extends your processing capabilities and reduces logistical movements through your factory, since the unit is placed directly next to the Voortman V303 or V310 plate processing machine.

Perfectly balanced with Evi

The success of any production is dependent on the balance between human interaction and machine automation. To contribute to success and maximize productivity, Voortman developed Evi. This software solution will help to boost the uptime and output, providing insight on the current status of machines, as well as tonnage and products produced during a specific timeframe. A clear and easy-to-use dashboard enables data analysis and explores instances of downtime. The cloud-based software tool also gives real-time information to machine operators, who are notified when their machine requires attention. Evi is designed to be accessible from any location and any device. Users always have access to the latest information.