At AMB 2024 in Stuttgart HAIMER will be showing how modern tool management works: with high-quality, process-reliable components, end-to-end digitization through to fully automated tool presetting and secure transmission of digital tool data to the machine. Striking highlights of the HAIMER booth are the fully digitized Tool Room set up on 30 m2 and the market-ready version of the fully automated tool preparation cell HAIMER Automation Cube One, which was presented for the first time a year ago.

Tool management must be made as easy as possible for manufacturing companies - whether small or large. End-to-end digitization and automation play a decisive role in this. HAIMER, the leading system partner for complete tool management, has designed its entire product range, which extends from tool holders, shrink-fit and balancing technology, tool presetters to carbide tools and touch probes, accordingly. It no longer "only" scores points for top quality but is also Industry 4.0-compatible.

At AMB 2024, HAIMER will be demonstrating what modern, future-proof tool management can look like, offering benefits for large and small companies alike. To this end, a complete "Tool Room of the Future" will be set up on 30 m2 of the booth area. "We offer our customers the analogue and digital tool setup process from a single source," emphasizes Andreas Haimer, President of the HAIMER Group. "Starting from our tool holders and tools as well as the Toolbase dispensing systems, the data is managed digitally by the WinTool software, right through to transmission to the machine tool control. Our HAIMER Power Clamp, Tool Dynamic and Microset machines are available for the analog setup process. That is unique!"

The WinTool data hub, which enables the management of tools, operating resources, machine programs, processes and master data, plays a central role in the overall process. "To provide our customers with a proven, high-performance, digital offering, we acquired a 25% share in WinTool AG at the beginning of the year and agreed on a strategic partnership with the TCM Group. Since then, their WinTool and Toolbase product lines have also been part of the HAIMER range," explains Andreas Haimer.

To ensure that the digital processes in tool management work reliably, the tools and their chucks should be identified as uniquely as possible. HAIMER therefore supplies all tool holders with a unique ID - in the form of a laser-engraved, unique data matrix code that prevents any mix-ups. In addition, a wide range of (set-up) information can be stored for each tool in the HAIMER Tool Room Manager (TRM) database and retrieved as required.

Innovations in the tool holder program

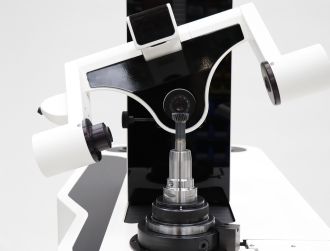

In addition to all the pioneering "digital" developments, the world market leader for tool shrinking and balancing technology is also presenting numerous innovations and improvements to the basic components, including the HAIMER Hybrid Chuck with patented hybrid chuck technology, available from the fourth quarter of 2024. This tool holder combines the advantages of two clamping worlds: the vibration-dampening properties of a hydraulic chuck with those of a high-precision, high-performance shrink chuck. Long-term tests have shown promising results: Compared to face mill arbors with indexable insert milling cutters, the Hybrid Chuck with solid carbide milling cutter reduced machining time by 30%. In addition, the tool life was more than five times longer, meaning that significantly more parts could be machined with one toolset.

New to the range is a large program of tool holders with polygonal shank taper PSC (ISO 26623) in HAIMER's usual top quality. This spindle interface is particularly suitable for turning/milling centers, as a fixed axial positioning and high torsional rigidity are achieved through torque transmission and centering via the polygonal taper with face contact. A wide variety of designs are available in sizes from PSC 32 to 63 (diameter of the face contact), from shrink-fit and collet chucks to Weldon and face mill arbors.

HAIMER is also expanding its range of tool holders with so-called micro collet chucks, i.e. high-precision collet chucks for micromachining with small machine interfaces (BT30 with face contact, HSK-E25, HSK-E40, HSK-E50)

Innovations in the tool holder program

In addition to all the pioneering "digital" developments, the world market leader for tool shrinking and balancing technology is also presenting numerous innovations and improvements to the basic components, including the HAIMER Hybrid Chuck with patented hybrid chuck technology, available from the fourth quarter of 2024. This tool holder combines the advantages of two clamping worlds: the vibration-dampening properties of a hydraulic chuck with those of a high-precision, high-performance shrink chuck. Long-term tests have shown promising results: Compared to face mill arbors with indexable insert milling cutters, the Hybrid Chuck with solid carbide milling cutter reduced machining time by 30%. In addition, the tool life was more than five times longer, meaning that significantly more parts could be machined with one toolset.

New to the range is a large program of tool holders with polygonal shank taper PSC (ISO 26623) in HAIMER's usual top quality. This spindle interface is particularly suitable for turning/milling centers, as a fixed axial positioning and high torsional rigidity are achieved through torque transmission and centering via the polygonal taper with face contact. A wide variety of designs are available in sizes from PSC 32 to 63 (diameter of the face contact), from shrink-fit and collet chucks to Weldon and face mill arbors.

HAIMER is also expanding its range of tool holders with so-called micro collet chucks, i.e. high-precision collet chucks for micromachining with small machine interfaces (BT30 with face contact, HSK-E25, HSK-E40, HSK-E50)

Future concept for tool presetting

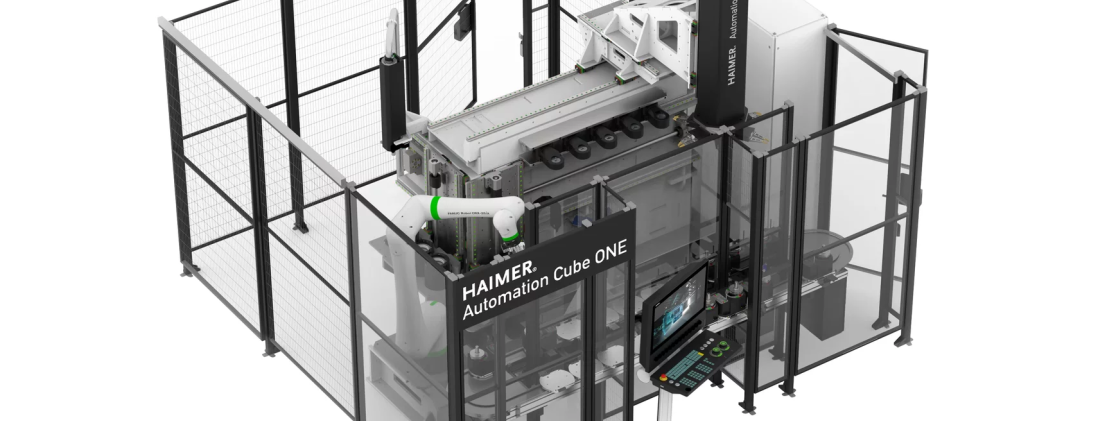

Last but not least - a top highlight at the HAIMER AMB booth is the Automation Cube One, the automated all-in-one tooling center for 24/7 tool supply. While the innovations mentioned so far make the production process easier for every machining company and can therefore also be used by small and medium-sized companies to increase efficiency, the Automation Cube One is aimed more at companies with the highest degree of automation and a large number of tool changes per day.

The HAIMER Automation Cube One is a robot cell that is built as solidly as a machine tool and is controlled by the latest Siemens Sinumerik One CNC. The Cube handles the shrinking and unshrinking as well as the measuring of complete tools automatically and can manage up to three different tool interfaces simultaneously. Up to eleven axes are available for parts handling. "Our Automation Cube One can shrink and unshrink a tool, measure it and transfer the data to the machine and databases in a matter of minutes," emphasizes Andreas Haimer. Compared to the prototype presented last year, the Automation Cube has also been equipped with measurement technology and sensors, making it capable of additional measurement tasks.