Artificial intelligence is entering the shopfloor

Artificial intelligence (AI) is moving from the research lab into daily use. Not fast enough, perhaps, in the view of those hoping to gain a significant competitive edge from AI. Rather sinisterly in the view of others who currently only have a vague idea of how self-thinking machines could change their everyday working lives. In the "Future of Business" focus topic at EMO Hannover 2023, the world's leading trade show for production technology, experts will be answering urgent questions about new business and working methods. Meanwhile, German universities are supporting AI by convincing local companies to implement AI applications, and by preparing employees to perform new tasks.

ProKI (ProAI), is playing a crucial role here. This is the name of an initiative launched by the WGP (German Academic Association for Production Technology) at the end of last year. Backed by 17 million euros of funding provided by the BMBF (Federal Ministry of Education and Research), a nationwide demonstration and transfer network is being set up at a total of eight locations to provide practical support for the implementation of AI solutions in industry. The initiative is coordinated by the WZL (Laboratory for Machine Tools and Production Engineering) at RWTH Aachen University. Taking part are institutes in Berlin, Darmstadt, Dresden, Hannover, Ilmenau, Karlsruhe and Nuremberg. In line with their respective research focuses, they are providing demonstrators and test environments for manufacturing companies in the fields of joining, forming, machining and coating.

Wide range of services provided free of charge to companies

"Each individual site is basically autonomous," explains Christian Fimmers, coordinator of the ProKI network. But they are in constant touch with each other. A common brand is to be set up with the same training formats, and there will be a website and social media activities aimed at achieving the greatest possible reach and maximum awareness. The services offered range from information events, personalized consultations, workshops and seminars through to practical support for company-specific projects. Participation is free of charge for companies. The overriding goal is to provide a point of contact for as many companies as possible with an interest in AI – especially small and medium-sized enterprises (SMEs).

Overcoming skepticism among SMEs

The institutes involved include the PtU (Institute for Production Engineering and Forming Machines) at TU Darmstadt. Christian Kubik, head of the Process Chains and Plants department, serves as the Center's managing director. More than 80 companies registered to take part in the first ProKI InfoPoint in Darmstadt. "The interest is there," Kubik notes. However, there is a certain amount of apprehension, especially among SMEs. This is reflected in skepticism about the technology, fears of losing control, a lack of expertise, and the fact that the ROI (return on investment) is not always easy to determine. The ProKI InfoPoints now take place online once a month. They last one hour and are divided into three 15-minute keynote presentations from academia and industry. The topics illuminate from different angles how the use of AI technologies can improve companies’ internal KPIs. Once interest has been aroused, a personal consultation is arranged. Opportunities for AI solutions are then explored. Finally, a visit is paid to the company. "Our motto is: Less talk and more action," Kubik emphasizes.

For many SMEs, the topic of artificial intelligence not only opens up new possibilities, but also brings new problems, at least initially. This applies to the development of a digital infrastructure for the factory as well as to employee training. "This, of course, raises the question of whether it makes sense to give a key production worker half a day off for training," Kubik admits. The time factor, he said, is a major hurdle, especially nowadays with the increasing shortage of skilled workers. Here, it is important for the initiative to show the necessary sensitivity, to determine the exact cost-benefit ratio and also to show how it is possible to take small steps in adopting the new technology. "The companies which are convinced and are really keen are already sending us their staff," Kubik says. Enhancing employees’ skills is the order of the day.

Experts wanted for the networked factory

The Competence Profiles in Digitally Networked Production study, which was put together at the WZL in Aachen with funding from the Hans Böckler Foundation back in 2020, showed how typical occupations in the metalworking industry are likely to change in the coming years. The researchers analyzed the activity structures of occupations such as industrial mechanics, toolmakers and cutting machine operators, including their main tasks in the areas of manufacturing, machine and plant operation as well as process monitoring. They linked these to identifiable technological trends, such as additive manufacturing, cloud technologies and the Internet of Production. It is expected there will be a significant increase in the complexity of the work involved and the required competencies, as well as in the need for companies to train specialists for the development, implementation and control of data-driven production processes and business models. According to the study, digital competence includes the will to change, the ability to use digital devices and an understanding of algorithms. However, trust in data also needs to be accompanied by critical thinking toward the quality of information. A holistic approach is required.

AI necessitating changes to the curriculum

The impact which the changes are having on the training and teaching curriculum has been apparent for some time. This is highlighted by the example of Trumpf, one of the world's largest suppliers of machine tools. According to the company, over half of last year’s new apprenticeships at its headquarters in Ditzingen (near Stuttgart) were IT-related. There is a new dual study program for cybersecurity specialists. The new training center in Ditzingen has its own Smart Factory. But while it is relatively easy to adapt the training curriculum to future requirements, many industrial companies are facing the major challenge of getting their existing employees fit for the future. Here, the Aachen researchers are advocating new approaches, such as the use of off-site learning factories, to meet the demand.

Algorithms for individualized training

But the question of what type of training is relevant and useful for each individual employee is no trivial matter. After all, it is not only individual aptitudes and skills that need to be taken into account, but also changing corporate goals that are influenced by technological developments, as well as the vast range of training possibilities. For some time now, specialized service providers have been using big data and AI tools to identify suitable training options.

The Kira Pro project (AI-based role navigation and identification of automated learning paths for further vocational training in the manufacturing sector) at the Fraunhofer Institute for Production Systems and Design Technology (IPK), Berlin, goes one step further. The project partners have set themselves the goal of developing and providing SME-appropriate AI solutions for the planning and realization of agile further training approaches. At the heart of the project is a “role navigator”, which identifies appropriate intermeshing programs from the large quantity of existing further training courses which are suitable for meeting a company’s goals, and from which customized and industry-specific learning paths can be drawn up for individual employees. For example, an appropriate learning path can be found for a mechatronics technician looking to take on a new role as a multi-machine operator, or a CAD designer keen to become a qualified 3D printing designer.

Protect knowledge, raise productivity

However, even the best training strategy will fail if companies start to lose knowledge which has been accrued over many years, whether through fluctuation or employees reaching retirement age. This is a particular problem in an industry renowned for producing machines with extremely long service lives. It is not uncommon for machine tools to remain operational for decades, after which time they are no longer state of the (automated) art and are highly dependent on the experience and knowledge of the machine operator.

Thomas Kessler, a development engineer at Herkules Wetzlar, is also familiar with this problem. The family-owned company, based in Solms-Oberbiel in central Hesse, has decades of experience in the field of bending and special-purpose machines as well as in the contract manufacturing of bent profiles. The production of curved profile components using three-roll bending is highly labor-intensive and requires a great deal of process know-how.

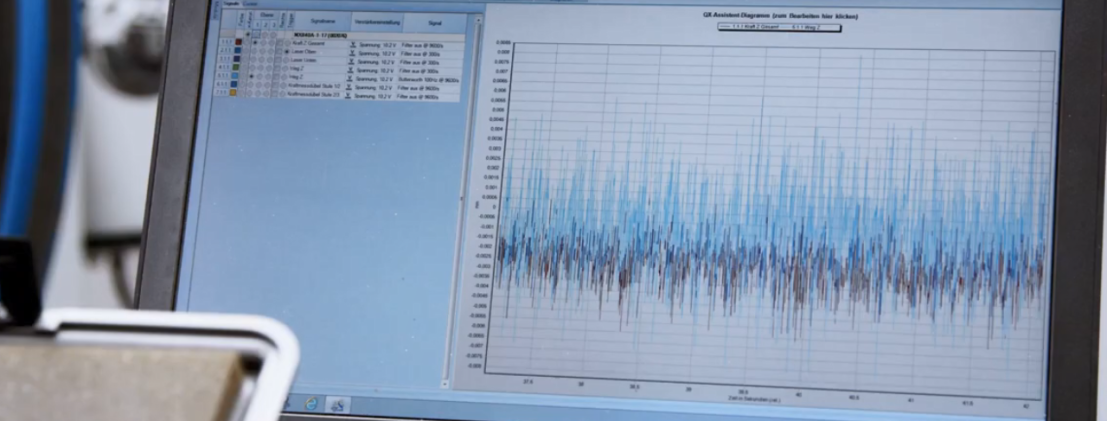

Herkules Wetzlar is involved in the MoDiPro (Modular Digitization for Profile Bending) project, in collaboration with the PtU Institute at Darmstadt Technical University and the Mühlheim-based IT specialist Angersbach + Kaiser Computer. Building on an older project for contour measurement, MoDiPro is a modular system that makes it possible to digitalize existing systems, irrespective of the manufacturer or the interface, and to automate the process control step by step, explains Thomas Kessler. The three-roll bending machine is equipped with sensor modules for this, allowing the recording of all process and product parameters necessary for process control. A machine learning model is to be used for data analysis. This will allow information about the machine and process to be utilized for the manufacture of parts in the future. It will enable employees to use the resulting automated bending process on an existing plant as an AI-supported assist system.

"We have an established track record of working very closely with the PtU Institute," says Thomas Kessler. Joint, publicly funded projects and interdisciplinary collaboration are the best way to find innovative solutions to problems and, ideally, to develop new business models from them. There is always an initial trigger for engaging with artificial intelligence, points out Kessler. A point must be reached at which conventional systems can no longer help, he points out. ProKI coordinator Christian Fimmers agrees. Despite all the impetus that comes from the scientists: "Companies’ own intrinsic interest is crucial here."