Laser multi-pass narrow-gap welding revolutionizes steel construction

Energy and resource efficiency are gaining ever more significance, which is why the Fraunhofer IWS has worked with partners to develop an alternative for conventional steel construction that not only constitutes a process technology solution, but also forms the basis for hardware and laser safety. This solution facilitates gentler machining of high-strength materials, as well as significantly reducing energy consumption and costs while greatly increasing process speed. The energy in-put required for the component can be reduced by up to 80 percent compared with conventional joining processes. Not only that, subsequent straightening of the component is eliminated entirely from the process.

Many technical structures feature some form of steel construction. Be it a container ship, railway vehicle, bridge or wind turbine tower, any one of these structures can have several hundred meters of welding seams. Conventional industrial processes such as metal active gas welding or submerged arc welding are usually used for this purpose. Here’s the problem: Due to the low intensity of the arc, a large proportion of the energy expended is not actually used in the welding process, but is lost to the component in the form of heat. The energy required for post-weld treatment is often of a similar magnitude to that required for the welding process itself. “These energy-intensive processes cause significant thermal damage to the material and result in severe distortion of the structure, which then demands very costly straightening work afterwards,” emphasizes Dr. Dirk Dittrich, who heads up the Laser Beam Welding group at Fraunhofer IWS.

Powerful laser welding process

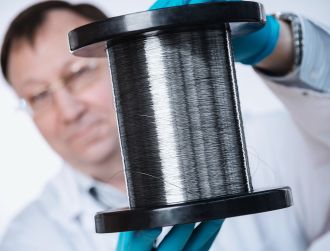

A team of researchers led by Dr. Dittrich has developed an energy-efficient alternative together with industrial partners as part of the “VE-MES – Energy-efficient and low-distortion laser multi-pass narrow-gap welding” project. Laser multi-pass narrow-gap welding (laser MPNG, see box below) uses a commercially available high-power laser and stands out from conventional methods thanks to its reduced number of layers and drastically reduced seam volume. These elements of the welding process are its key benefits.

“Depending on the component, we can reduce the energy input for the component during welding by up to 80 percent, and we can lower filler material consumption by up to 85 percent compared to conventional arc processes,” reports Dr. Dittrich. “What’s more, it was not necessary to carry out a straightening process on the component studied. As a result, we can cut production time and costs, process high-strength steel materials and significantly improve the CO2 balance of the entire production chain. Given the significant number of steel structures being built in Germany and around the world, this could prove to be hugely advantageous.” This is because the high intensity of the laser beam guarantees that the energy input is highly localized at the welding point, whereas the surrounding areas of the component remain comparatively cold.

“The welding time is also reduced by 50 to 70 percent,” says Dittrich, citing another advantage. The new process also excels in terms of weld seam quality – the seams are significantly slimmer and the edges are virtually parallel, whereas in conventional welding processes the seams are V-shaped. “If laser welding were used in steel construction processes, it would become a unique selling point for medium-sized businesses in Germany and strengthen its market position in the face of international competition,” says Dittrich with confidence. “We are providing the industry with an efficient form of joining technology that is set to revolutionize steel construction on account of its cost-effective application and resource-saving production process.”

Steel girders for indoor crane construction

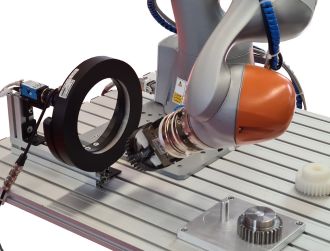

The researchers from Fraunhofer IWS demonstrated the performance of their new development using a practical example from indoor crane construction. They deployed the new welding technology using special system technology and an integrated beam protection concept. The design of the experimentally built, four-meter-long rectangular profile of an indoor crane segment conformed to the design and manufacturing guidelines of comparable, conventionally produced components. Weld seams typical of the application were produced: a butt joint on 30-millimeter plates and a fully joined T-joint (15-millimeter plate).

For a one-meter weld seam, it was possible to reduce the costs for a sheet thickness of 30 millimeters by 50 percent compared with submerged arc welding, including the subsequent straightening process. For sheet thicknesses of less than 20 millimeters, where metal active gas welding processes are also commonly used, the potential cost savings are even higher at up to 80 percent. The cost savings in terms of welding filler materials alone can amount to more than 100,000 euros per year for larger companies. In addition, the laser beam sources used offer great potential for stemming rising energy costs due to their high efficiency (approximately 50 percent) and good process efficiency (reduction of energy input by 80 percent). With this evidence of practical suitability, the approach can now be extended to other applications.