Advancing Semiconductor Precision: The Role of Spatial Light Modulators

As the semiconductor industry continues to push the boundaries of miniaturization and complexity, the demand for precise, high-speed optical solutions has never been greater. Devices capable of operating with nanometer accuracy and exceptional programming speeds are critical within semiconductor manufacturing and across other high-tech industries. Spatial light modulators (SLMs) developed by Fraunhofer IPMS have emerged as pivotal tools. Leveraging custom-designed tilting and piston mirror systems, these advanced modulators are already used for semiconductor applications. Their potential extends even further, promising transformative contributions to fields such as material processing, 3D holographic displays, and biomedical imaging.

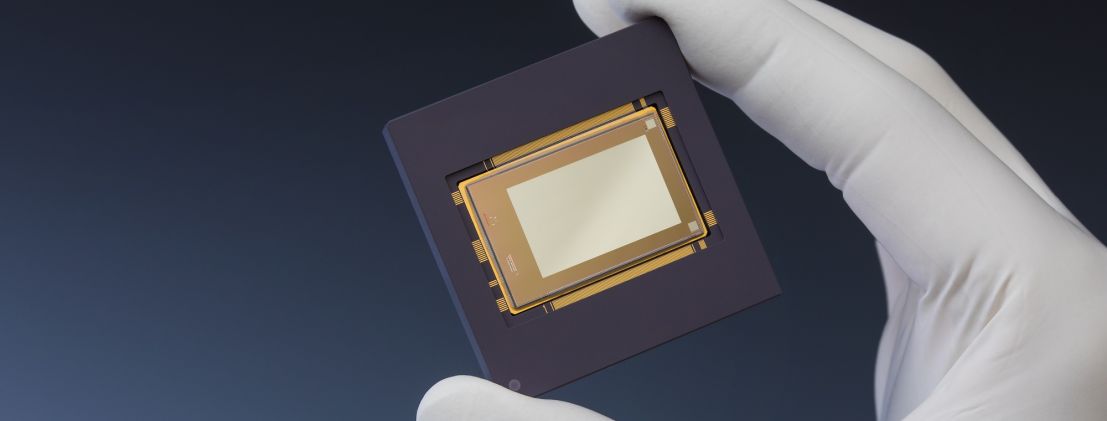

A spatial light modulator consists of several million mirrors on a single semiconductor chip. The tiny mirrors form a micromirror array and, depending on the type of mirror, can be tilted along one or two axes or pulled down individually. This allows them to control and manipulate direction, intensity or phase of light. These spatial light modulators are suitable for a wide range of applications.

1-axis tilting mirrors enable the generation of optical patterns and the structured illumination of surfaces. Gray-level pattern projection is applied for microlithography where patterns are transferred into photoresist. Light modulation in the UV and DUV range is a special expertise of Fraunhofer IPMS. Furthermore, 1-axis tilting mirror devices enable a programmable microscope illumination which can be utilized for a non-destructive investigation of sensitive biological samples.

Spatial light modulators can concentrate broad light beams into strong laser spots. The 2-axis tilting mirrors redirect incident light into a large number of beamlets and enable precise control of their directions with minimal loss of light. They are therefore ideal for applications with high light intensities or efficiencies, such as laser ablation or laser engraving.

Piston mirror arrays can generate holographic 3D images in real-time. They are promising key components for real holographic 3D head-up displays. The high-precision piston mirror technology also offers potential applications in the field of adaptive optics or optical tweezers.

Easy technology transfer and novel concepts for customers

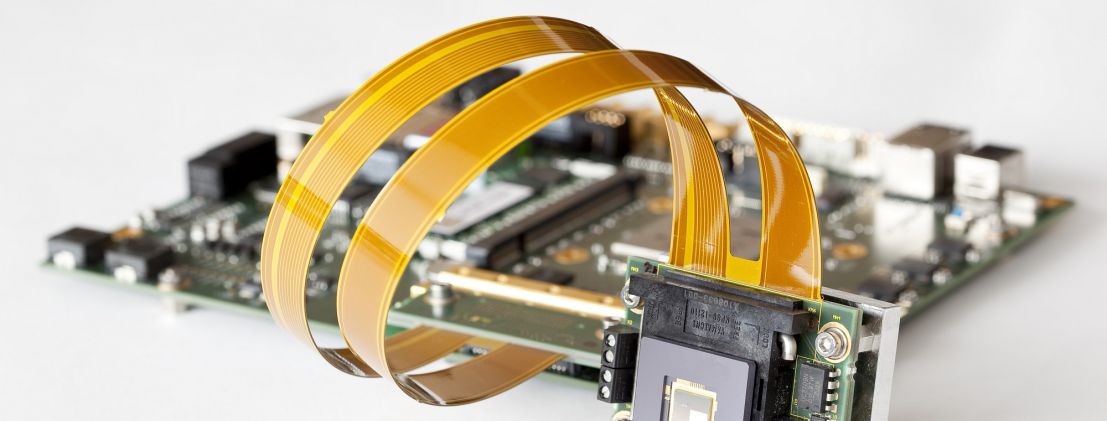

To enable technology transfer of the systems into applications, Fraunhofer IPMS offers customer evaluation kits with 64k (256x256) mirrors, which contain either tilting or piston mirror arrays. In addition to the micromirror chip, the Fraunhofer IPMS kit includes control electronics and software. Customer support is offered as well.

At SPIE Photonics West, Fraunhofer IPMS will present initial research results on highly integrated 512x320 micromirror arrays with a novel “Piston-Tip-Tilt” actuator concept. In the future, this will open up new possibilities for wavefront control up to the mid-infrared range.

SPIE Photonics West

From January 25 to January 30, 2025, Fraunhofer IPMS will attend the conference and trade fair for photonic technologies - SPIE Photonics West - in San Francisco. The institute will present its research and development results at booth #4623 in Hall F as well as within conference presentations. Appointments with experts in the fields of spatial light modulators, micro scanners and microdisplays can now be booked on the Fraunhofer IPMS website.