GreenBotAI Makes Robots More Flexible and Reduces Their Energy Consumption

Smaller batch sizes instead of mass production, more complex production lines, increasing competitive pressure, unstable supply chains: Against this background, the Franco-German research project GreenBotAI addresses robotics. Three main objectives are in focus - ensuring production continuity even in pandemic times, strengthening Europe's independence in production automation, and significantly reducing the energy consumption of robot applications in European factories.

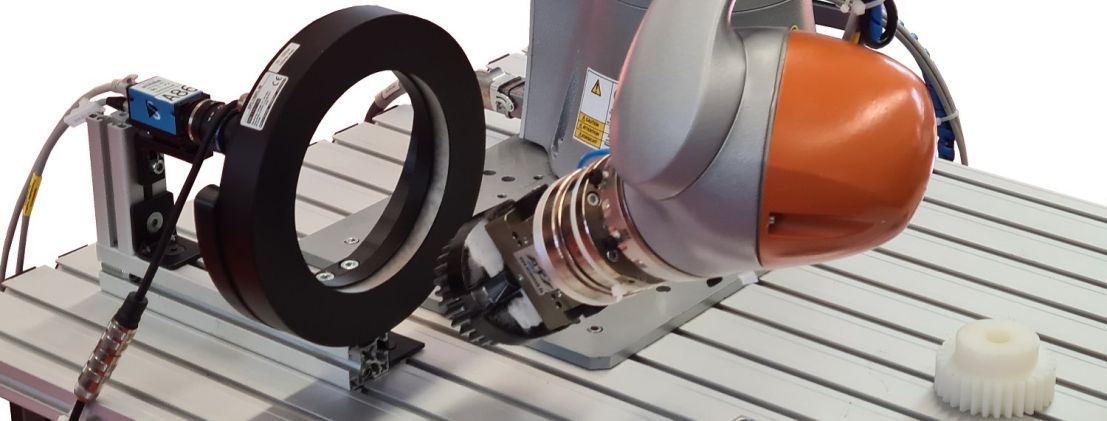

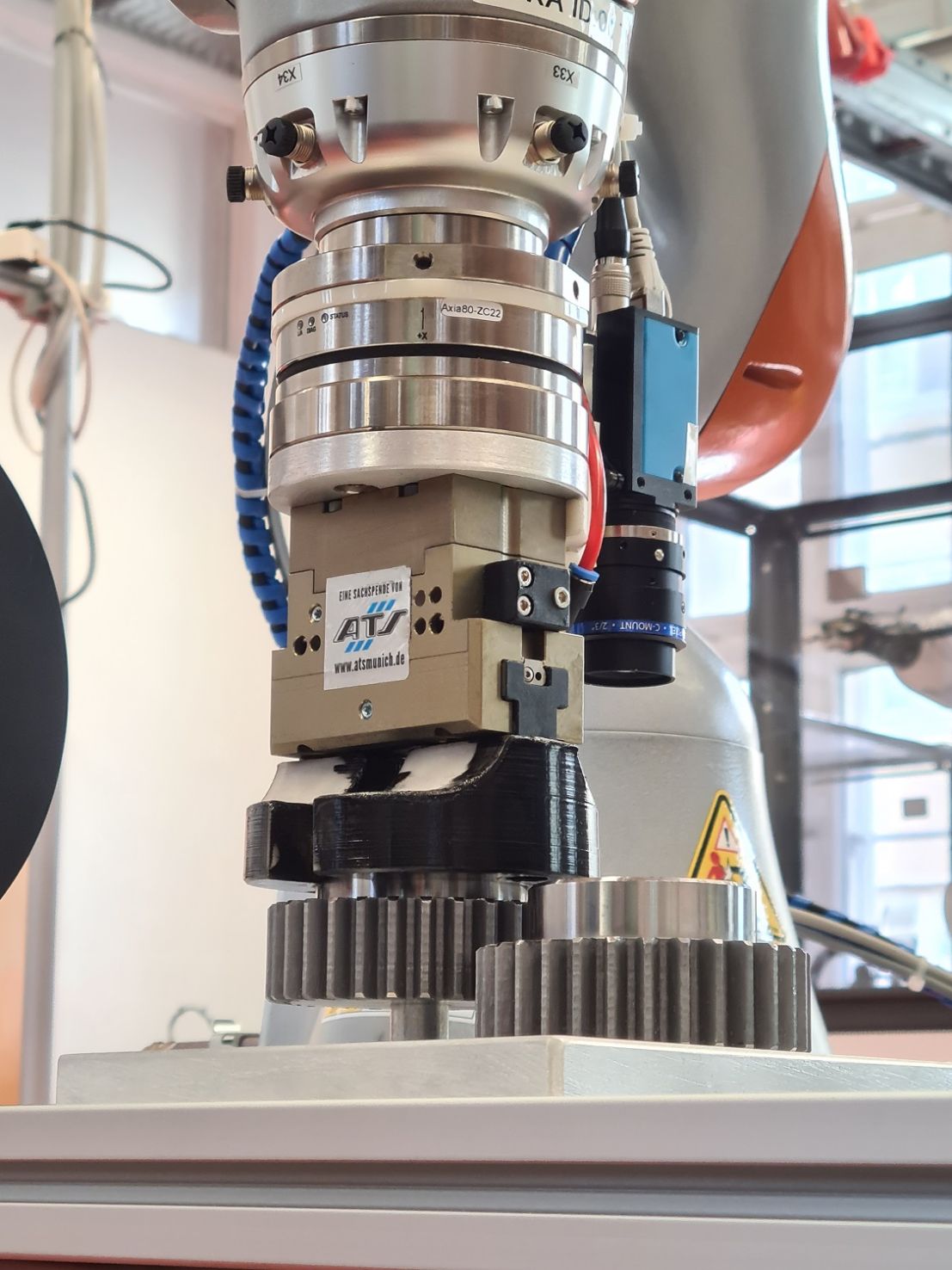

Technically, GreenBotAI focuses on the reaction and latency times in industrial robotics, optimized path planning, and executing well-defined tasks while the robot is in motion ("on the fly"). Without stopping, for example, it is possible to capture 2D images for object recognition for the desired handling or assembly task. In this Franco-German research project, Fraunhofer IWU leads the consortium.

For intelligent and flexible robotics

The project focuses on an agile approach to handling materials and workpieces. AI algorithms are supposed to give manufacturing more flexibility and accelerate production in various industrial sectors. The goal is intelligent robotics capable of handling complex tasks spontaneously. Required components in hardware, state-of-the-art deep learning methods for monitoring, improvements in data processing and error control, are expected to herald a generational shift in robotics.

Reducing energy consumption without replacing robots

GreenBotAI is working on several levers to reduce energy consumption by up to 25 percent. These include data-reduced AI models, accelerated gripping tasks, and reduced computing power.

Controlling complex motion sequences with simple image information

At the Hannover Messe, the project partners demonstrate what they have achieved as yet. An individual image taken in 2D with industrial camera technology ("One-Shot Demonstration") of the component and little computing power are sufficient for the robot to pick up, inspect, and position this component as desired. The software Xeidana®, developed at Fraunhofer IWU, verifies whether the robot has picked up the correct component. Guests at the booth can try it out themselves: They place a gear at any point on a table in the workspace of a collaborative robot (a robot designed for collaboration with people). Based on the image information, the software determines the positions of all objects relative to the robot, calculates the robot's path, and determines the gripping position. The robot then picks up the gear, and inspects it, relying entirely on the image information. This is where real-time evaluation of force data comes into play, guiding the robot on how to fit the picked-up gear into a second gear, using a smart application of AI that mimics human touch. A digital twin additionally visualizes all real actions of the robot. Visitors can also experience the assembly and integrated quality control application live.

Project partners in GreenBotAI include Fraunhofer IWU, Munich University of Applied Sciences (Faculty of Applied Natural Sciences and Mechatronics), software developer INBOLT SAS, and École Nationale Supérieure d'Arts et Métiers (ENSAM LISPEN). The German Federal Ministry for Economic Affairs and Climate Action is the funding provider on the German side.