New Open Data Format Simplifies 3D Printing Process

Various 3D printing processes for metals are used in the industry. Along the process chain, the design data must be converted several times. This produces data volumes in the double-digit gigabyte range. Processing them not only takes time but also pushes IT systems to their limits. A research team from RWTH Aachen University (Chair of Laser Technology LLT and Chair of Digital Additive Production DAP) and the Fraunhofer Institute for Laser Technology ILT has tackled the problem and developed a new data format that simplifies data processing for metallic 3D printing processes.

Their new Open Vector Format (OVF) is designed not only to accelerate 3D printing but also to simplify the scaling of manufacturing plants. Distributed data processing and, thus, the control of networked plants become possible: Here we see Industry 4.0 in practice.

Why a new data format?

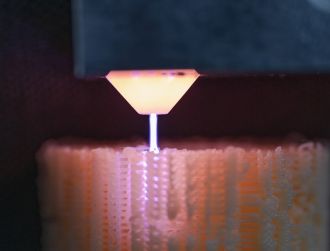

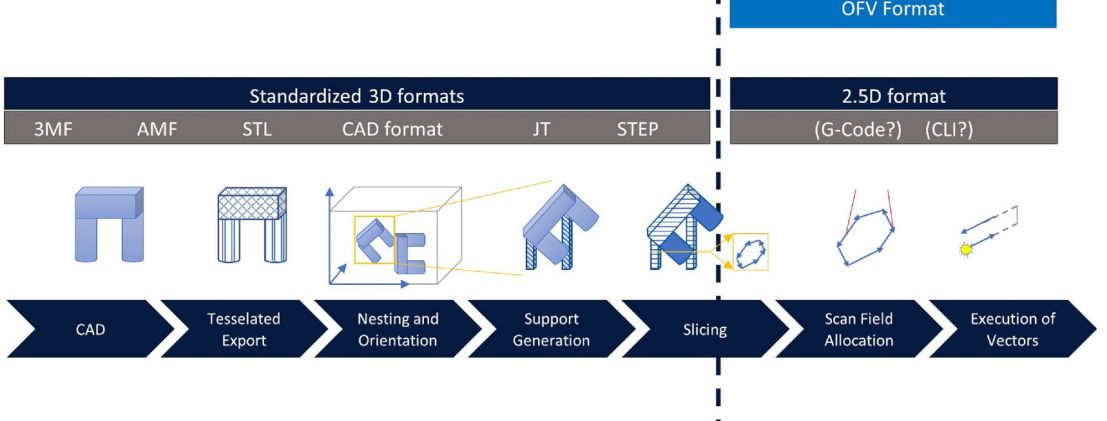

To understand the need for a new data format, it is useful to look at the processes involved in laser powder bed fusion (LPBF). First, the component is designed with a CAD program. In the second step, the contours of the component are converted into the smallest geometric structures, usually triangles (“tessellation“). In the next step, the component is virtually fitted into the installation space. It is rotated and, if necessary, fitted into the virtual space with other parts in such a way that the volume is used optimally (“nesting and orientation“). For this purpose, any support structures are inserted into the design. Up to this point, the data are managed as three-dimensional coordinates.

In the next step, 3D structures are converted into individual layers for the LPBF process (“slicing“). This is necessary because the LPBF system always applies a layer of powder, fixes the structures with the laser and then moves on to the next layer. In addition to the 2D contours in the respective layer, instructions for machine control are required here.

At this exact point a need for “Open Vector Format” arises: While sufficient formats exist for 3D design data, after slicing the data is processed primarily via proprietary solutions from the individual manufacturers of the LPBF systems. But even the standardized solutions such as the G-code format from the field of CNC machines or the CLI format (common layer interface) are not satisfactory. G-code, for example, is based on storing the coordinates in text format (ASCII), which quickly swells the data volume to several tens of gigabytes. Accordingly, the time needed to process these data volumes is practically unacceptable.

What can the new format do?

First of all, this new solution, OVF, provides users with open structures, so that they can easily access the geometry data. This data is stored in a vector format oriented to the manufacturing process, which drastically reduces the size of the files compared to the previous text format. In addition, manufacturing information is stored in OVF. This concerns, for example, the laser power or delay times during the scanning process. The scan-feed-allocation, i.e. the distribution to several beam sources, is also stored in OVF for multi-beam systems. In detail, the format is based on the open source technology “protocol buffers,“ which Google also uses for structured data and which are defined by an interface description language (IDL), which was used to define the OVF data.

Based on binary data, the format is readable for six programming languages supported by Google, plus 30 other languages can also work with it. The important thing is the layered processing of the data, which enables control over a network and greatly reduces local data storage. Experimental comparisons have shown that the new format is processed at a similar speed as proprietary formats of machine manufacturers, i.e. considerably faster than other open formats such as G-code.

Integrate process monitoring, control via networks

Things get interesting when it comes to process monitoring: If the contour of the workpiece is to be compared with nominal data during machining, then users need access to the design geometry and must be able to compare it to the data from the 3D measurement. Such tasks were an important reason for developing the format.

OVF allows system developers to combine LPBF machines with image processing of their own choice and link the data. On the one hand, this improves quality assurance. On the other, it allows the performance of different LPBF systems to be compared. This also works in interconnected facilities, i.e. when several LPBF systems including process monitoring are controlled via a network.

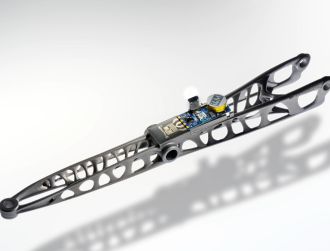

Application in microstructuring

Automatically comparing target and actual data as well as supporting a machine control via the network are, of course, also relevant topics for ablative processes such as laser micromachining. Both are important reasons why researchers at RWTH Aachen University and Fraunhofer ILT are interested in applying the OVF format beyond the additive community. One example is a multi-beam process, with which many small holes are drilled simultaneously. A camera is then used to check whether these are also completely drilled or whether they are partially closed. By comparing the camera data with the target geometry, users can decide where postprocessing is necessary. The instructions for the postprocessing can be programmed in OVF.

For the community, with the community

Using an open-source system was an important concern for the programmers. As researchers, they want to achieve an optimal solution independent of manufacturers with input from the entire 3D community. The definition of the format is available on GitHub. Tools for converting other formats to OVF are also available there. In addition, validation software is available there that can be used to check OVF datasets. The next step is to create a slice viewer that can be used to visualize individual layers. Find the OpenVectorFormat on GitHub.

Currently, the format is being used in laboratories at RWTH Aachen University and Fraunhofer ILT. However, the researchers are also talking with two manufacturers of 3D processing software and a scanner manufacturer, all of whom want to integrate the format into their software.