Sheet metal materials on the virtual test bench

Increasing demands on sheet metal forming processes require ever more extensive experimental characterizations of the original base materials. At the same time, the characterization tests used are constantly facing new challenges due to the use of thinner sheets of metal. The Virtual Lab of the Fraunhofer Institute for Mechanics of Materials IWM in Freiburg provides a remedy for this: It determines the necessary characteristic values for the design of sheet metal forming processes via simulation. The Fraunhofer IWM is cooperating with the University of Twente in the Netherlands to further develop the Virtual Lab.

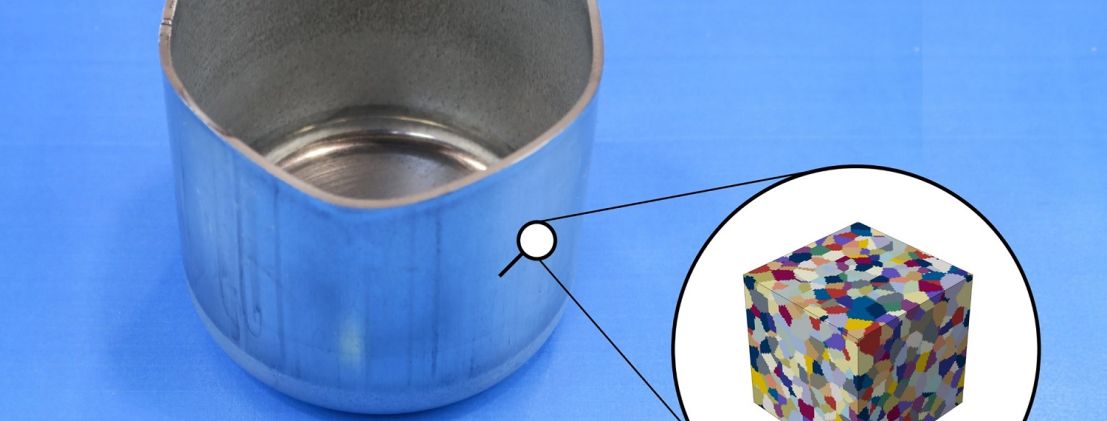

Sheet materials, like those used for complex car chassis, efficient plate heat exchangers, or commercially available beverage cans, have a distinctive feature: Their material properties vary based on the direction in which the sheets are formed or loaded. Within industry, it is extremely important to precisely know this material behavior in order to properly design the sheet metal forming process and thus be able to manufacture the component with high dimensional accuracy. The experimental determination of the direction-dependent material properties required for this is becoming increasingly extensive, and not every load condition in the manufacturing process can be realized in experiments. For example, the determination of these material properties is critical under compression loading. In addition, sheet metal components are becoming increasingly fragile and thin-walled. As a result, many materials — such as metal foils, which are required in battery technology — are difficult to characterize experimentally because they form wrinkles or crack extremely quickly. For these materials, there is consequently not enough experimental data on which to fall back.

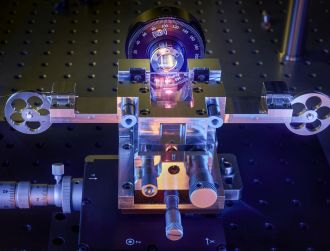

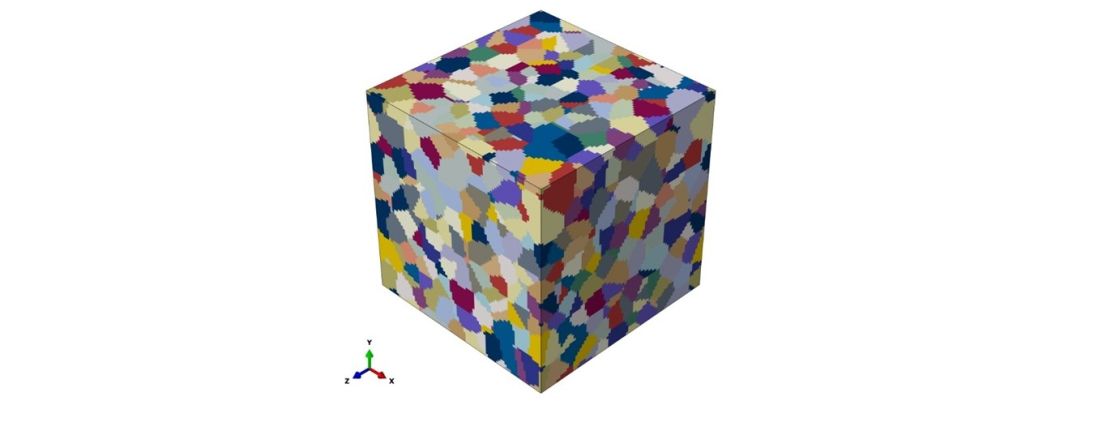

With its Virtual Lab, the Fraunhofer IWM has created a way to fill this gap. “Using simulations, we determine the directional dependence of the mechanical properties in sheet metal materials,” explains Alexander Wessel, a scientist at the Fraunhofer IWM in the Forming Processes Group. “In doing so, we map the materials at the microscale level in a microstructure model and predict the macroscopic direction-dependent material behavior based on the underlying physical mechanisms.” In this way, it is possible to characterize sheet materials as well as to determine the corresponding material parameters for designing the forming processes, whereas this is not possible via experiment alone. “Our approach in the Virtual Lab allows us to manage with just a few experimental data points and calculate the missing data ourselves,” Wessel states. The time and financial outlay are therefore significantly lower compared to a purely experimental characterization. For companies, this means shorter development times and cost savings when introducing new forming processes.

Hand in hand with the University of Twente

In order to further enhance the predictive quality of the Virtual Lab and expand the economic benefits for industry, there is a new cooperation between the Fraunhofer IWM and the University of Twente in the Netherlands. Since October 2022, Alexander Wessel has been working at the University of Twente as part of the “Fraunhofer International Mobility Program,” or FIM for short, as a member of Professor Ton van den Boogaard’s renowned research group, which also conducts research on forming processes. With the FIM program, the Fraunhofer-Gesellschaft financially supports strategic partnerships with foreign research institutions and thus strengthens international scientific exchange.

The aim of Alexander Wessel’s stay in the Netherlands is primarily to compare the various simulation approaches and improve the prediction accuracy of the Fraunhofer IWM Virtual Lab. “The current results show that there is still potential for optimization, such as in the prediction of direction-dependent material properties in age-hardenable aluminum alloys, for example,” says Wessel. In collaboration with Assistant Professor Semih Perdahcioglu from the University of Twente, an initial modeling approach has been developed to solve this problem. The task now is to further improve this approach and integrate it into the Virtual Lab. It is expected that this will increase the prediction accuracy for heat-treatable aluminum alloys, such as those used for car bodies in automotive construction.