Okuma Supports Complete Machining thanks to Advanced Technologies

In today's fast-paced manufacturing landscape, the demand for precision, efficiency, and adaptability in CNC machining continues to surge. As industries become more specialized, the tools and technologies supporting them must evolve to meet these exacting standards. Okuma’s premium solutions take the cutting performance of its high-performance machines to a new level and enable complete machine processes with advanced technologies.

Okuma's dedication to advancing CNC machining technologies is evident in its latest offerings, which focus on enhancing cutting performance while ensuring energy efficiency and cost-effectiveness. By seamlessly integrating advanced technologies into their machines, Okuma enables manufacturers to achieve complete machining processes with unmatched precision and efficiency.

Eight different technologies

-

Auto Attachment Head Compensation automatically sets compensation values for the rotation of the tool head, providing support for efficient and precise machining. -

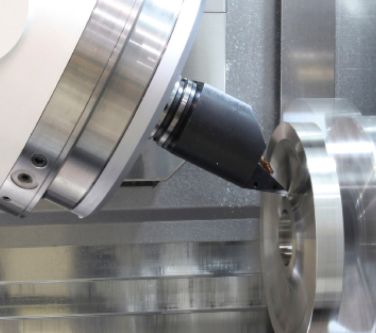

B-axis turning allows curved surfaces to be turned efficiently without changing tools. The X, Y and B axes are all controlled simultaneously to turn curves at the best angle and without offsets. -

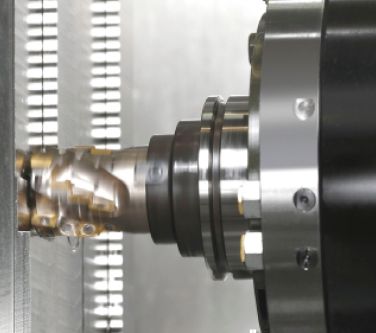

Dynamic Tool Load Control measures the concentricity and position of each cutting edge of an insert milling cutter and adjusts the feed rate for each cutting edge individually. -

Flat-Tool Grooving is a process that produces an airtight groove with the use of grooving steel and without post-processing. The spindle is synchronised with the movement of the X-Y axis.

-

Okuma’s Gear Machining Package is a hardware and software extension for Turning and Milling Centres that simplifies the programming and cutting of gears by selecting the tool type, workpiece data and machining parameters. -

The Hyper-Surface function detects changes in programmed shapes and ensures a consistent feed rate. This improves surface quality and reduces machining time. -

NC Gage enables complex measuring tasks on Turning and Milling Centres. It reduces set-up times and allows the machine to detect and correct geometry errors. -

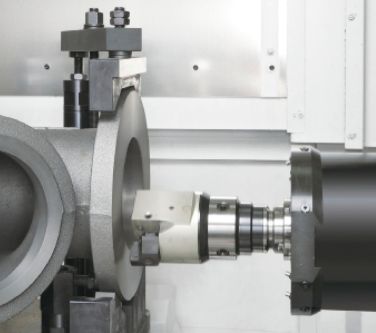

Turn-Cut allows a turning process to be mapped onto Machining Centres or Multitasking Machines. the turning movements are interpolated along the X and Y axes, and the spindle angle is synchronised.