Okuma Enhances 5-Axis Machining for Simpler, Faster, and More Precise CNC Operations

5-axis simultaneous machining offers clear advantages over traditional 3-axis or indexed 3+2 methods: higher precision, reduced setup time, and the ability to complete complex geometries in a single operation. Yet its adoption is often limited by complexity and cost. Okuma addresses these challenges with an improved generation of 5-axis machining centres, combining advanced functionality with user-friendly operation and long-term cost efficiency. Designed for sectors demanding high precision and reliability — including aerospace, energy, automotive, and tool and mould-making — these machines support efficient, high-speed manufacturing with minimal manual intervention.

Simplifying Access to Simultaneous Machining

Performance and Cost-Efficiency in One

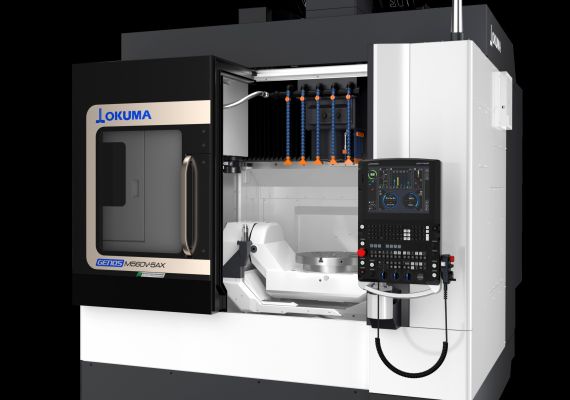

Okuma’s 5-axis machining centres offer compelling value, often outperforming traditional 3-axis solutions over the long term. Unlike 3-axis machines, which require additional software or hardware to approach similar performance levels, Okuma’s machines deliver advanced capabilities as standard. For instance, the GENOS M560V-5AX, equipped with 60 tool stations and X-Y-Z travel of 1,050 x 560 x 460 mm, is capable of machining a wide range of materials with high precision. The MU-4000V-L expands this functionality by combining turning with 5-axis multitasking for complex, high-speed, and high-precision operations. For heavy-duty applications, the VTM-2000YB features a swivelling B-axis spindle with a wide angular range and robust linear axes supported by generously dimensioned flat guides, ensuring both flexibility and machining stability across larger workpieces.