Integrated Sensor Technology: The Next Step in Additive Manufacturing

The Fraunhofer Institute for Laser Technology ILT will be presenting the latest research results in additive manufacturing technology at the Fraunhofer joint stand at Formnext in Frankfurt am Main from November 7 to 10, 2023. Among other things, the Aachen engineers will be showing additively manufactured sensors that are printed directly onto components and that can provide real-time data for predictive maintenance. A new process makes it possible to seamlessly insert sensors into a component during the additive manufacturing process Laser Powder Bed Fusion (LPBF).

Trends such as Industry 4.0 and the Internet of Things are making the precise recording of the condition of machines and components increasingly important. To face the challenges of collecting sufficient data, the Fraunhofer Institute for Laser Technology ILT has developed a sensor infrastructure for smart industrial applications and implemented it using additive manufacturing processes.

Usually, sensors are manually attached to the surfaces of components. In addition to sensors on the component surface, the newly developed process can also integrate sensors directly into the components. This way, important characteristic data about the load within the component can be collected.

Manual application of sensors is often not accurate enough; after all, the sensors must register vibrations, accelerations or the smallest deformations in the µm range. Samuel Moritz Fink, Group Leader Thin Film Processes at Fraunhofer ILT explains: "Manual application of sensors is too imprecise and not reproducible in many cases. In addition, users are increasingly demanding processes that can be automated."

Printed sensors for more precision

The Fraunhofer Institute for Laser Technology ILT will be exhibiting a passenger car transverse link with an additively manufactured sensor at the Fraunhofer joint stand (hall 11, booth D31) at Formnext in Frankfurt am Main from November 7 to 10, 2023. "The force sensor that we printed on the transverse link is less than 200 µm thick, including the insulation and protective layer as well as electrical connections," says Fink. "We can determine the forces acting in the application at any given time." The sensor continuously measures the change in force during cornering, for example, and warns of defects before they occur.

"The force sensor registers the smallest cracks that occur before they lead to component failure," says the group leader. In addition to a force sensor, other sensors can also be applied to a component, for example, to detect temperature, vibrations or sound, pressure or acceleration, light, tension, different gases and liquids. Special polymers for the insulating and protective layers can withstand temperatures of up to 300 °C.

The range of applications for this process is immense, especially because it provides reliable real-time data for predictive maintenance: "It can be used, for example, to monitor battery cells individually, optimize maintenance intervals for offshore wind turbines or improve processes in mechanical and plant engineering," continues Fink.

Multi-stage process for manufacturing smart components

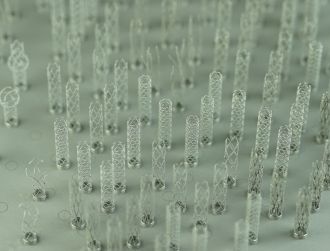

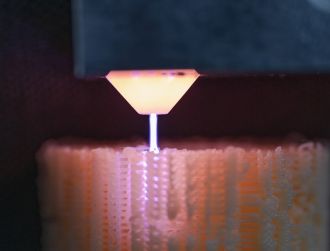

Another remarkable innovation presented by Fraunhofer ILT at Formnext is the seamless integration of sensors during the additive manufacturing process. With the help of 3D structural printing processes such as laser powder bed fusion (LPBF), printed sensors can be integrated directly into components as they are created.

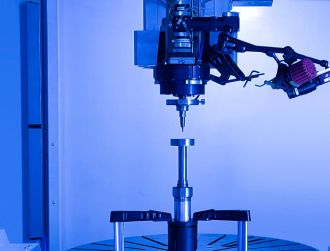

The Fraunhofer researchers will demonstrate this technology with an additively manufactured milling head. The structural printing process using LPBF is interrupted to integrate strain gauges using a digital functional printing process and laser-based thermal post-treatment. The structural printing process is then continued to complete the smart part.

By combining structural and functional printing with laser-based post-treatment, the institute has shown that components with integrated sensor technology can be manufactured completely additively. This not only enables them to precisely place sensors for sophisticated condition analysis, but also to protect these sensors from mechanical environmental stress.

"The geometry of the sensors can be customized depending on the component. In the future even additional functional elements such as integrated heaters are conceivable," says Samuel Fink. "This technology opens up a wide range of possible applications, from manufacturing in the areas of toolmaking and mechanical engineering to the automotive industry and beyond in the energy, aerospace and aeronautics sectors."