GF Machining Solutions brings Additive Manufacturing to industrial level

At Formnext 2022, which will be held in Frankfurt am Main (Germany) from 15-18 November, GF Machining Solutions will present how its solutions and its unique approach enable bringing metal 3D printing to an industrial level. On GF Machining Solutions' booth, visitors will have the opportunity to follow the complete manufacturing of an AM part.

GF Machining Solutions will exhibit several highlights on its booth, located in Hall 11, C59. The AM Ecosystem includes a metal 3D printer, the DMP Flex 350 Dual, 3DXpertTM software solutions, the Wire-cutting EDM machine CUT AM 500, the 5-axis Milling machine MILL S 200 U with Automation, as well as the System 3R Tooling for AM solutions, allowing for automation of post-process steps. Applications presented on the booth not only show how to benefit from this complete offer, but also demonstrate the expertise of GF engineers to advise companies on Design for Manufacturing.

In-situ control device prototype

Together with the DMP Flex 350, GF Machining Solutions will present a prototype of an in-situ control device using electromagnetic imaging. This technology, which is compliant with NDT standards widely used in the metal industry, has been developed by the Swiss company AMiquam SA and has been integrated into the DMP Flex 350 in the frame of a partnership. This partnership has been supported by ETH Zurich inspire AG. The unique stand-alone plug-and-play electromagnetic system allows companies in regulated markets such as aerospace or healthcare to collect information on AM process stability with quality assessment on porosity or defects, in compliance with international standards and regulatory bodies.

In partnership with 3D Systems, GF Machining Solutions will present two new materials added to its parameters portfolio — Certified HX and Certified CuCr2.4. Both materials are certified for use with the company’s DMP Flex 350 and DMP Factory 350 3D printers, and HX is also certified for the DMP Factory 500 to address a range of applications requiring high strength and corrosion resistance in industries such as energy, industrial gas turbines (IGT), high tech, consumer goods, aerospace and defense, and automotive.

Certified HX and certified CuCr2.4

Certified HX is a high-performance nickel alloy that contains a higher percentage of molybdenum (up to 9.5%) compared to other nickel alloys, which enhances its strength and resistance to corrosion, creep deformation, cracking, and oxidation in hot zone environments. This material is ideal for applications with a service temperature of up to 1200°C. With superior printed part quality and part density (typically 99.9%), Certified HX is ideal for producing tall, large parts with integrated cooling and flow channels in optimal orientation for the energy, industrial gas turbine (IGT), petro-chemical, as well as the aerospace and defense industries. Typical applications are hot zone stator blades and integrated stators, impellers, turbine vanes, drilling tools, and combustion components that benefit from the high service temperature of the HX material.

“The DMP Factory 500, together with the new printing parameters for the HX nickel alloy, allows us to scale our Additive Manufacturing services by delivering large cross-section parts such as combustion chamber casings, stators, and impellers,” says Marco Salvisberg, Business Development Manager, Additive Manufacturing, GF Casting Solutions. “The high heat deflection temperature of the HX material, combined with surface smoothness, part accuracy, narrow tolerances and high repeatability of the DMP Factory 500 printing process, addresses the essential performance requirements of these parts and critical features such as cooling channels. Our customers rate DMP part quality as the best in the industry today.”

The other material added to GF Machining Solutions' portfolio, Certified CuCr2.4, is a high-strength, corrosion-resistant copper alloy that is significantly stronger than pure copper and easier to process for Additive Manufacturing applications. Its superior part density (typically 99.9%) and high conductivity after heat treatment make CuCr2.4 ideal for heat management and cooling systems in the high-tech, consumer goods, automotive, aerospace and defense industries, especially when strength is also a requirement.

New metal AM applications

In terms of featured applications, GF Machining Solutions will display unique large-size parts printed with the large printing solution DMP Factory 500. Key parts shown are an optimized Industrial Gas Turbine (IGT) component built with new Certified HX parameters, a combustion chamber for rocket engine built in Laserform Inconel 718, developed in collaboration with GF Casting Solutions, and a compressor impeller built-in Laserform Inconel 718 and co-developed with GF Machining Solutions' partner Oerlikon AM.

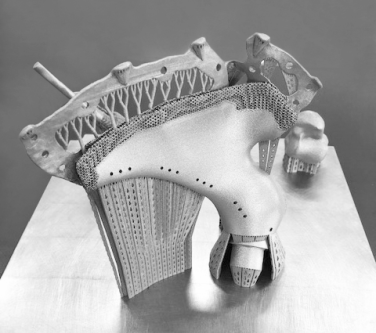

An impressive panel of patient-specific implants, built-in Laserform Titanium Grade 23 by our customer Koln3D with the DMP Flex 350, and a hydraulic manifold used in the semiconductors industry and built-in Laserform Stainless steel 316L will also be showcased. Another highlight at the booth will be an optimized hybrid-cutting tool, printed in Boehler M789 and developed with GF Machining Solutions' customer Kuhn.

Finally, GF Machining Solutions will present a new application, called flushing heads, printed in Laserform Stainless steel 316L. These flushing heads are already used today for the conventional Wire-cutting EDM solutions, the CUT X series. They have drastically improved the cutting performance of these machines thanks to revolutionary flushing performances.

-

Combustion chamber for rocket engine built with LaserformTM Inconel 718 and manufactured on the DMP Factory 500 by GF Casting Solutions. -

Heat exchanger built with Certified CuCr2.4. -

Hydraulic manifold used in the semiconductors industry and built with LaserformTM Stainless steel 316L. -

Industrial Gas Turbine component built with Certified HX parameters and manufactured on the DMP Factory 500 by GF Casting Solutions. -

Real patient-specific scapula implant designed by Koln3D and printed with Laserform Titanium Grade 23. -

The 3D printed shoulder implant is a very good example of GF Machining Solutions' unique expertise in Design for Manufacturing and the AM Ecosystem.